ASTM B366 UNS N10665 Hastelloy B2 Butt Weld Fittings

Introduction

In industries where corrosion resistance and durability are paramount, Hastelloy B2 butt weld fittings stand out as a superior choice. These fittings, made from the nickel-molybdenum alloy Hastelloy B2, are designed to withstand some of the most aggressive environments, making them ideal for chemical processing and other demanding applications. This article delves into the characteristics, applications, and benefits of ASTM B366 UNS N10665 Hastelloy B2 butt weld fittings, showcasing their role in enhancing the performance and reliability of piping systems.

Understanding Hastelloy B2

What is Hastelloy B2?

Hastelloy B2 is a nickel-molybdenum alloy known for its excellent resistance to hydrochloric acid and other strong reducing agents. It offers outstanding corrosion resistance in both oxidizing and reducing environments, making it suitable for a wide range of applications.

Key Properties of Hastelloy B2

- Corrosion Resistance: Exceptional resistance to hydrochloric acid, sulfuric acid, and other aggressive chemicals.

- Thermal Stability: Maintains its mechanical properties and corrosion resistance at elevated temperatures.

- Weldability: Excellent weldability, allowing for the fabrication of complex piping systems without compromising performance.

Characteristics of ASTM B366 UNS N10665 Hastelloy B2 Butt Weld Fittings

Seamless Connections

Hastelloy B2 butt weld fittings provide seamless connections between pipes, ensuring a leak-free and efficient flow of fluids. The welding process creates a strong joint that can withstand high pressures and temperatures.

Versatility

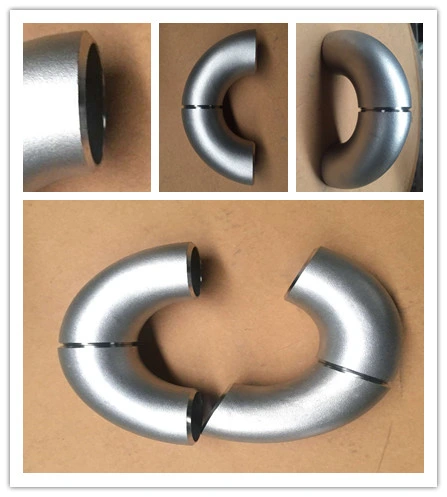

These fittings are available in various shapes and sizes, including elbows, tees, reducers, and caps, allowing for versatile configurations in piping systems. They can be customized to meet specific requirements, ensuring optimal performance.

Durability

Made from high-quality Hastelloy B2, these butt weld fittings offer exceptional durability and longevity. They resist corrosion, oxidation, and wear, ensuring reliable operation in the most demanding environments.

Applications of Hastelloy B2 Butt Weld Fittings

Chemical Processing

In chemical processing plants, Hastelloy B2 fittings are preferred due to their resistance to corrosive chemicals and high temperatures. They ensure the safe and efficient transport of hazardous substances.

Pharmaceutical Industry

Hastelloy B2 fittings are used in the pharmaceutical industry to maintain the purity and integrity of products. Their smooth surfaces and resistance to corrosion make them suitable for sterile environments.

Petrochemical Industry

In the petrochemical industry, Hastelloy B2 fittings are used to handle aggressive chemicals and high-temperature processes. Their durability and corrosion resistance ensure long-term reliability and safety.

Waste Treatment

Hastelloy B2 fittings are employed in waste treatment facilities to handle corrosive waste streams and prevent contamination. Their resistance to chemical attack ensures the safe and efficient processing of waste.

Benefits of Using Hastelloy B2 Butt Weld Fittings

Superior Corrosion Resistance

Hastelloy B2 fittings offer superior corrosion resistance, ensuring long-lasting performance in aggressive environments. This reduces maintenance costs and extends the lifespan of piping systems.

High Strength

The high strength of Hastelloy B2 butt weld fittings allows them to withstand high pressures and temperatures, making them suitable for demanding applications.

Cost-Effectiveness

While Hastelloy B2 fittings may have a higher initial cost, their durability and low maintenance requirements make them a cost-effective choice in the long run.

Conclusion

ASTM B366 UNS N10665 Hastelloy B2 butt weld fittings are indispensable components in modern piping systems, offering seamless connections, durability, and versatility. Their excellent corrosion resistance and high strength make them suitable for a wide range of applications, from chemical processing to waste treatment. As industries continue to demand reliable and efficient piping solutions, these Hastelloy B2 fittings will remain a preferred choice for enhancing the performance and reliability of piping systems.

FAQ

1. What are the main advantages of Hastelloy B2 butt weld fittings?

The main advantages include superior corrosion resistance, high strength, and excellent weldability, making them suitable for demanding applications.

2. In which industries are Hastelloy B2 fittings commonly used?

Industries such as chemical processing, pharmaceuticals, petrochemicals, and waste treatment commonly use these fittings due to their excellent properties.

3. How do Hastelloy B2 fittings enhance the performance of piping systems?

Their corrosion resistance, high strength, and durability ensure reliable operation and reduce maintenance costs, enhancing overall system performance.

4. Are Hastelloy B2 butt weld fittings cost-effective?

Yes, their durability and low maintenance requirements make them a cost-effective choice in the long run, despite a higher initial cost.

5. What is the significance of ASTM B366 in relation to Hastelloy B2 fittings?

ASTM B366 is a standard specification for factory-made wrought nickel and nickel alloy fittings, ensuring the quality and performance of Hastelloy B2 fittings.

You must be logged in to post a comment.