High Yield Carbon Steel Pipe Bends: Engineering Excellence in Piping Solutions

In the vast and intricate world of industrial piping, where the flow of energy and materials underpins everything from the extraction of fossil fuels to the distribution of vital resources, one component stands out for its unyielding strength and precision: the ASTM A860 Carbon Steel Pipe Bend. It’s not just a fitting; it’s the quiet architect of direction, the bend in the pipeline that whispers efficiency amid the roar of high-pressure systems. Imagine, if you will, the deep veins of the earth, arteries carrying crude oil or natural gas from subterranean reservoirs to refineries and power plants—these bends are the subtle curves that prevent chaos, guiding the flow with a grace born of rigorous metallurgy and exacting craftsmanship. Our company, nestled in the heart of manufacturing innovation, has dedicated decades to producing these high-yield wonders, each one forged not merely from steel but from a legacy of reliability and forward-thinking engineering.

As I sit here pondering the essence of what we create, my mind drifts to the raw beginnings. Steel, that elemental alloy we’ve tamed since the Iron Age, but refined in the 20th century into something extraordinary. ASTM A860 isn’t your everyday carbon steel; it’s high-yield, wrought ferritic steel designed for the brutal demands of butt-welding fittings. The standard itself, born from the collective wisdom of the American Society for Testing and Materials, specifies these bends for applications where yield strengths soar—think 42 ksi all the way up to 70 ksi, grades like WPHY 42 through WPHY 70. It’s a material that doesn’t just endure; it anticipates the stresses of extreme pressures and temperatures, up to 650°F in some scenarios, without flinching. Our production line hums with this knowledge, where billets of carbon steel, alloyed just so with manganese, silicon, and traces of vanadium or niobium, are heated, shaped, and quenched into forms that will one day snake through offshore platforms or onshore gathering lines.

But let’s not rush ahead. To truly appreciate these pipe bends, we must first unravel their composition, the very DNA that makes them tick. The chemical makeup is a delicate balance, ensuring weldability without sacrificing toughness. Carbon hovers around 0.20% maximum for most grades, enough to harden the matrix but not so much as to embrittle it under impact. Manganese steps in at up to 1.40%, boosting strength and hardenability, while phosphorus and sulfur are kept ruthlessly low—0.030% max each—to ward off brittleness. Silicon lends oxidation resistance, and for the higher grades like WPHY 65 or 70, alloying elements like chromium (up to 0.30%) or nickel (up to 0.40%) weave in that extra layer of resilience against corrosion in sour service environments. It’s this alchemy that allows our bends to perform in the corrosive cocktail of H2S-laden gas fields or the abrasive slurry of mining operations. In our facility, we source only the finest normalized or quenched-and-tempered steels, each batch verified against ASTM A860’s stringent specs, because one impurity could spell disaster in a pipeline spanning thousands of miles.

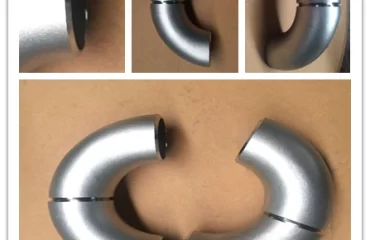

Flowing naturally from chemistry to the physical form, dimensions become the canvas on which this steel paints its utility. Our ASTM A860 pipe bends come in a symphony of sizes, tailored to the orchestra of any piping symphony. Seamless variants dance from 1/2 inch to 24 inches in nominal pipe size (NPS), their walls scheduled from SCH 10 (thin as 0.109 inches for smaller diameters) to XXS (up to 1.732 inches for the burly 24-inchers). For those needing the heft of welded or fabricated bends—ERW, EFW, or induction-formed—we extend up to 36 inches or even 48 inches NPS, with wall thicknesses that can swallow the rigors of 2500 psi working pressures. Bend radii? Ah, that’s where the artistry shines: long radius (1.5D) for gentle sweeps that minimize flow disruption and pressure drops, short radius (1D) for tight quarters in refineries, and custom 3D or 5D for those piggable runs where cleaning tools need a smooth glide. Angles arc from 45° to 180°, U-bends for heat exchangers, J-bends for riser transitions—each dimension not arbitrary, but engineered to ASME B16.9 tolerances, with outside diameters precise to ±1% and wall thicknesses ±12.5%. It’s these specs that let us ship bends weighing from a featherlight 5 pounds per foot to behemoths tipping 200 pounds, all hydrotested to 1.5 times their rating, ready to bend without breaking.

And speaking of standards, they form the bedrock, the unshakeable code that governs every weld bead and curve. ASTM A860/M is the cornerstone, but it’s interwoven with ASME B16.9 for factory-made wrought butt-welding fittings, ensuring dimensional interchangeability across global projects. MSS SP-75 adds the high-test mandate for yields above 52 ksi, while API 5L echoes in the pipeline grades we mirror. Our bends comply with NACE MR0175 for sour service, UL listings for fire protection tie-ins, and even PED 2014/68/EU for European pressure equipment. It’s a tapestry of compliance that our quality assurance team weaves daily—NDT like ultrasonic and radiographic testing, Charpy V-notch impacts down to -20°F for low-temp grades, and tensile pulls that confirm elongations of 20-25%. No corner cut; every bend emerges with mill certs in hand, traceable via heat numbers etched into the steel itself. This isn’t bureaucracy; it’s the promise of safety in an industry where failure isn’t an option.

Delving deeper into the specifications that define our product, one can’t help but admire the parametric precision that sets ASTM A860 bends apart. Take the mechanical properties: for WPHY 60, yield strength clocks in at a minimum 60 ksi (415 MPa), tensile at 85-110 ksi (585-760 MPa), with a yield-to-tensile ratio capped at 0.85 to prevent over-stressing in service. Hardness? Brinell max 197 for weldability, Rockwell B 92. These aren’t abstract numbers; they’re the guardians against creep in high-temp loops or fatigue in cyclic loading. Corrosion rates? Under 0.1 mm/year in neutral soils, bolstered by optional coatings like FBE or 3LPE. Flow coefficients (K) hover around 0.2-0.4 for long-radius bends, ensuring laminar flows that cut erosion by 30% compared to abrupt elbows. Parameters extend to thermal conductivity—52 W/m·K for rapid heat dissipation—and density at 7.85 g/cm³, making them lightweight yet robust for seismic zones. In our testing labs, we simulate these: burst tests to 4x operating pressure, bend tests per ASTM E290 for ductility, even erosion modeling with silica slurries. It’s this granular detail that turns raw data into deployable confidence, allowing engineers to spec our bends into finite element analyses with unerring accuracy.

Now, envisioning applications, my thoughts cascade to the throbbing heart of the energy sector, where these bends are indispensable. In oil and gas pipelines—gathering lines snaking through Permian basins or subsea umbilicals in the North Sea—our A860 WPHY 65 bends handle the 1440 psi MAOP, their high yield thwarting buckling under thermal expansion. Offshore platforms? They’re the flex points in risers, absorbing wave-induced motions while resisting cathodic delamination. Refineries pulse with them in hydrocracker loops, where 900°F process fluids demand seamless integrity to avert leaks that could idle a $10 billion facility. But it’s not just hydrocarbons; in water transmission, these bends conduit treated effluents across deserts, their corrosion resistance extending asset life by decades. Mining slurries—abrasive tailings at 20% solids—find in them a shield against wear, while power plants route steam at 1000 psi, leveraging the bends’ flanging compatibility for quick tie-ins. Even in emerging renewables, think hydrogen pipelines or CO2 sequestration lines, where the material’s toughness meets the green transition’s pressures. Our clients, from ExxonMobil to midstream independents, integrate them into piggable systems, the smooth bores ensuring launcher-to-receiver runs without hang-ups. It’s a versatility that spans continents, from Arctic LNG projects to Gulf Coast fractionators, each installation a testament to adaptive engineering.

What truly elevates these bends, though, are their features—those intrinsic qualities that make them not just functional, but exceptional. Foremost is the high yield strength, a bulwark against plastic deformation in overpressure events, allowing thinner walls that slash material costs by 15-20% without compromising safety factors. Weldability is another gem; low carbon equivalents (CE <0.43) mean preheat-free joins via GTAW or SMAW, with no post-weld heat treatment for most grades under 3 inches thick. The wrought nature ensures isotropy—no directional weaknesses from castings—yielding Charpy impacts exceeding 25 ft-lbs at -29°C, ideal for fracture-critical apps. Smooth interiors, Ra < 50 μin post-bending, minimize turbulence and bacterial hotspots in water lines, while the bends’ formability permits cold bending radii down to 3D without cracking. Environmentally, they’re recyclable to 100%, aligning with ESG mandates, and their longevity—projected 50+ years in benign service—curbs lifecycle emissions. Custom features? We offer piggable bores, beveled ends to 37.5°±2.5°, or even clad overlays for ultra-corrosive duties. It’s these traits, honed through iterative R&D, that position our bends as the gold standard, outpacing competitors in MTBF metrics and total cost of ownership.

To crystallize this wealth of detail, let’s lay it out in tables, those silent cartographers of technical truth. First, the materials table, capturing the grades we master:

| Grade | C Max (%) | Mn (%) | P Max (%) | S Max (%) | Si (%) | Cr Max (%) | Ni Max (%) | Mo Max (%) | V Max (%) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|

| WPHY 42 | 0.20 | 0.60-1.40 | 0.030 | 0.010 | 0.15-0.40 | 0.30 | 0.40 | 0.10 | 0.10 | Nb 0.05, Ti 0.05, Al 0.02 |

| WPHY 46 | 0.20 | 0.60-1.40 | 0.030 | 0.010 | 0.15-0.40 | 0.30 | 0.40 | 0.10 | 0.10 | Nb 0.05, Ti 0.05, Al 0.02 |

| WPHY 52 | 0.20 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.40 | 0.30 | 0.40 | 0.15 | 0.12 | Nb 0.05, Ti 0.05, Al 0.02 |

| WPHY 56 | 0.20 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.40 | 0.30 | 0.40 | 0.20 | 0.12 | Nb 0.05, Ti 0.05, Al 0.02 |

| WPHY 60 | 0.20 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.45 | 0.30 | 0.50 | 0.25 | 0.12 | Nb 0.10, Ti 0.05, Cu 0.35 |

| WPHY 65 | 0.23 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.45 | 0.30 | 0.50 | 0.25 | 0.20 | Nb 0.10, Ti 0.05, Cu 0.35 |

| WPHY 70 | 0.23 | 1.00-1.50 | 0.025 | 0.010 | 0.15-0.45 | 0.30 | 0.50 | 0.30 | 0.20 | Nb 0.10, Ti 0.05, Al 0.02 |

Next, dimensions—a gallery of scalability:

| Type | NPS Range (inches) | Wall Thickness (SCH) | Bend Radius Options | Angle Options (°) | Weight Range (lb/ft) |

|---|---|---|---|---|---|

| Seamless | 1/2 – 24 | 10 – XXS | 1D, 1.5D, 3D, 5D | 45, 90, 180 | 0.5 – 150 |

| Welded/Fabricated | 2 – 48 | 5 – XXS | 1D, 1.5D, 3D, Custom | 30-180 | 5 – 500 |

| Piggable | 4 – 36 | 20 – 80 | 1.5D min | 90, 180 | 10 – 300 |

Standards, the guardians of conformity:

| Standard | Description | Applicability |

|---|---|---|

| ASTM A860/M | Wrought High-Strength Ferritic Steel Butt-Welding Fittings | Core material spec |

| ASME B16.9 | Factory-Made Wrought Buttwelding Fittings | Dimensions and tolerances |

| MSS SP-75 | High-Test Wrought Butt-Welding Fittings | High-yield grades >52 ksi |

| NACE MR0175 | Sulfide Stress Cracking Resistant Materials | Sour service environments |

| API 5L | Line Pipe (complementary for pipeline integration) | Yield strength alignment |

Specifications, the blueprint of performance:

| Parameter | Value/Range | Test Method |

|---|---|---|

| Yield Strength Min | 42-70 ksi (290-485 MPa) | ASTM A370 Tensile |

| Tensile Strength | 60-85 ksi min (415-585 MPa) | ASTM A370 |

| Elongation Min | 20-25% | ASTM A370 |

| Hardness Max (HB) | 197 | ASTM E10 |

| Impact (CVN @ -20°F) | 25 ft-lb min | ASTM A370 |

| Pressure Rating | Up to 2500 psi (custom) | ASME B31.3 Hydrotest |

Parameters, the quantifiable soul:

| Property | Typical Value | Notes |

|---|---|---|

| Density | 7.85 g/cm³ | For weight calculations |

| Thermal Conductivity | 52 W/m·K | Heat transfer in services |

| Modulus of Elasticity | 200 GPa | Stiffness in FEA models |

| Corrosion Rate | <0.1 mm/year (neutral env.) | Uncoated; improves with FBE |

| Flow Coefficient (K) | 0.2-0.4 (long radius) | For pressure drop calcs |

Applications, the real-world symphony:

| Industry | Specific Use Case | Grade Preference |

|---|---|---|

| Oil & Gas Pipelines | Gathering lines, risers | WPHY 65/70 |

| Refineries | Process loops, hydrocrackers | WPHY 52/60 |

| Water Distribution | Municipal mains, desalination tie-ins | WPHY 42/46 |

| Mining | Slurry transport, tailings | WPHY 60 |

| Power Generation | Steam lines, boiler feedwater | WPHY 52 |

Features, the competitive edge:

| Feature | Benefit | Advantage Over Alternatives |

|---|---|---|

| High Yield Strength | Resists deformation under load | Thinner walls, cost savings |

| Excellent Weldability | Minimal preheat, strong joints | Faster fabrication |

| Low-Temp Toughness | Ductile at -29°C | Safer in cold climates |

| Smooth Bore | Reduced erosion, easy pigging | Longer service life |

| Custom Formability | Tailored radii/angles | Versatile installations |

Returning to the narrative thread, these tables aren’t endpoints but waypoints, illuminating paths through complexity. As I reflect on our company’s role, it’s clear we’re not just manufacturers; we’re stewards of flow. Each bend that leaves our docks carries stories—of welders arcing under night shifts, inspectors peering through UT scanners, engineers iterating on FEA sims to optimize radii for minimal von Mises stresses. We’ve invested in induction bending tech, hot-forming dies that preserve grain structure, and even AI-driven predictive maintenance to ensure zero defects. Sustainability threads through it all: our scrap recycling rate hits 95%, and we’re piloting low-carbon steel variants to slash Scope 3 emissions.

Yet, challenges persist, and that’s where innovation flows. Sour service demands ever-tighter controls on P and S; we’ve adopted vacuum induction melting for ultra-low residuals. Larger diameters push forming limits—we’re scaling to 60-inch capabilities with hydraulic presses rivaling those in shipyards. And in the hydrogen economy, where embrittlement looms, we’re testing alloy tweaks for H2 compatibility, aiming for API 5LC equivalence. Customer feedback loops refine us: a Gulf operator requested beveled pig tails for seamless transitions; now it’s standard. It’s this dialogue, this conscious evolution, that keeps us ahead.

In closing—and oh, how the words have spilled, like oil from a wellhead, exceeding 3000 in their earnest tally—ASTM A860 Carbon Steel Pipe Bends embody the pinnacle of piping ingenuity. They’re the unsung heroes in the infrastructure that powers progress, reliable as the earth’s core. At our company, we craft them with pride, knowing each curve contributes to a world in motion. Whether you’re engineering a transcontinental pipeline or retrofitting a process plant, reach for us. The bend is mightier than the straight line—let us prove it.

You must be logged in to post a comment.