Der Auslass besteht aus hochfestem, niedrig legiertem Material und seine Zugfestigkeit beträgt über 600 MPa und der hydrostatische Prüfdruck über 24 MPa. Sein Sicherheitsfaktor beträgt über 2,5, was viel höher ist als die inländischen Industriestandards. Wir versprechen es 100% nicht explodierend im Standard-Arbeitsdruck und garantieren eine hohe Abriebfestigkeit mit Sicherheit .

Diese verschleißfesten Rohrsysteme müssen daher für Monate ausgelegt sein, sogar Jahre, von extremer Beanspruchung aufgrund der abrasiven Natur des Betons, mit Drücken von gepumpt 2000 An 3000 psi bei hoher Geschwindigkeit. Any disruption due to a failure in the piping system can be costly—literally halting construction—because concrete will harden quickly and once it does, the piping must be replaced before pouring can resume.

The inner of our products is made of imported alloy steel tube with Cep> 0.75%,characterized by high carbon,high alloy,high precion,and material wall thick well-proportioned. We can promise the average concrete conveying amount is more than 60000 Kubikmeter .

“When you install a concrete pipeline you have to factor in that the higher up you go, the more pressure is created and the greater the wear,” says Paul Turney, Amherst’s concrete pumping manager. “It’s very labor intensive to replace broken pipes, not to mention the delay in construction, so you have to counteract all that by making sure the wall material can stand up when pushing concrete 700 feet vertically.”

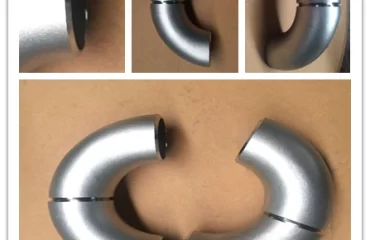

Other piping system elements include boom and lay-down systems, elbows and bends, Reduzierstücke, back-end kits, endet, adapters, couplings and gaskets. The company’s 5-inch and 6-inch two-bolt high pressure coupling, zum Beispiel, has been tested to handle 15,000 psi static loading without any sign of failure.

The company’s line of concrete-specific products is anchored by its pipe systems, from 2-inch to 6-inch I.D, which are made abrasion-resistant via a unique induction hardening process. It begins with a steel pipe manufactured to a proprietary chemistry, followed by induction heating, and finally water quenching of the inner surface to create a single wall pipe that can last up to 3 An 5 times longer than mild steel.

Compared with the single pipes and Induction concrete pump ,our twin-wall pipes is money saving .Using our topest pipes can greatly reduce the frequence of repairing and replacing ,and put and end to the extra compensation and legal disputes because of sudden pipes exploding,which can also reduce the cost up to 30%-50%.

Du musst sein angemeldet um einen Kommentar zu veröffentlichen.