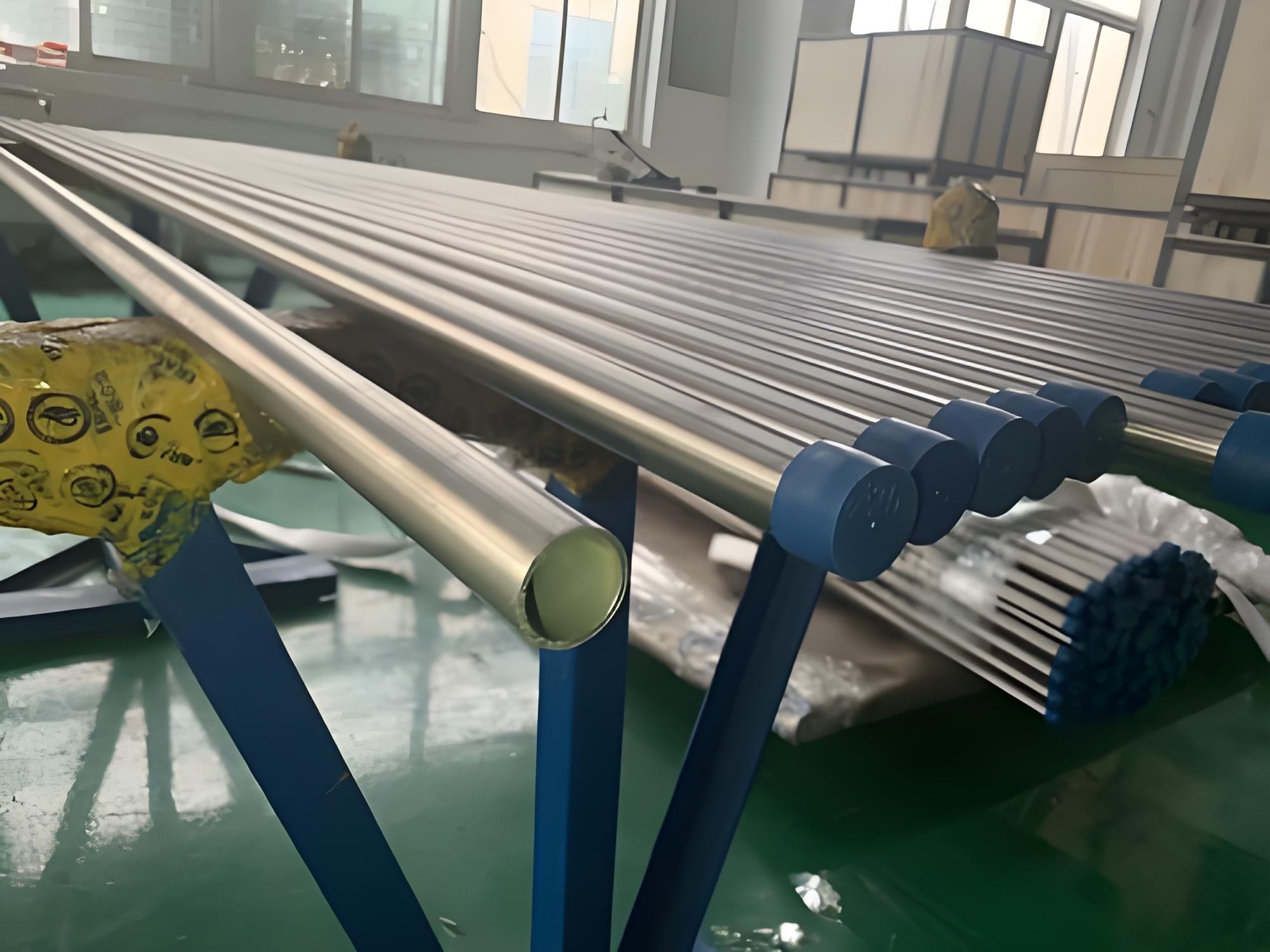

HASTELLOY® X Alloy Seamless Pipe | ASTM B622, ASTM B829, ASME SB622, ASME SB829

Overview of HASTELLOY® X Alloy Seamless Pipe

HASTELLOY® X alloy (UNS N06002, W86002) is a nickel-chromium-iron-molybdenum superalloy engineered for exceptional performance in high-temperature and corrosive environments. Renowned for its oxidation resistance, high-temperature strength, and fabricability, this alloy is ideal for seamless pipes used in demanding applications across aerospace, chemical processing, petrochemical, and power generation industries. HASTELLOY® X seamless pipes, manufactured to ASTM B622, ASTM B829, ASME SB622, and ASME SB829 standards, offer superior resistance to stress-corrosion cracking, thermal fatigue, and oxidation up to 2200°F (1200°C). The alloy retains excellent ductility after prolonged exposure to temperatures of 1200°F (650°C), 1400°F (760°C), and 1600°F (870°C) for up to 16,000 hours, ensuring long-term reliability.

Key features include:

- High-Temperature Performance: Maintains structural integrity in extreme heat, ideal for gas turbine and furnace applications.

- Corrosion Resistance: Resists oxidation, chloride-induced stress corrosion cracking, and pitting in aggressive environments.

- Fabricability: Excellent forming and welding characteristics for complex pipe configurations.

- Standards Compliance: Meets stringent ASTM and ASME specifications for seamless pipe quality and performance.

Specifications of HASTELLOY® X Seamless Pipe

HASTELLOY® X seamless pipes are manufactured to precise industry standards, ensuring consistent quality and performance. The following table outlines key specifications as per ASTM B622, ASTM B829, ASME SB622, and ASME SB829.

| Parameter | Details |

|---|---|

| Alloy Designation | HASTELLOY® X (UNS N06002, W86002) |

| Standards | ASTM B622 (Seamless Pipe/Tube), ASTM B829 (General Requirements), ASME SB622, ASME SB829 |

| Pipe Type | Seamless |

| Size Range | Outer Diameter (OD): 1/8″ to 8″ (3.175 mm to 203.2 mm) Wall Thickness: SCH 10, 40, 80, 160, XXS Length: Up to 12 meters (custom lengths available) |

| Surface Finish | Annealed, Pickled, Polished, Mill Finish |

| Testing | Hydrostatic, Eddy Current, Flattening, Flaring, Tensile, Hardness |

| Certifications | ISO 9001, EN 10204 3.1/3.2, ASTM/ASME Compliance |

| Heat Treatment | Solution Annealed at 2150°F (1177°C), Rapid Cooled |

Standards Explanation:

- ASTM B622/ASME SB622: Specifies seamless nickel and nickel-cobalt alloy pipes and tubes for general corrosion-resistant and high-temperature service.

- ASTM B829/ASME SB829: Provides general requirements for nickel alloy seamless pipes, including tolerances, testing, and marking.

These standards ensure that HASTELLOY® X seamless pipes meet rigorous quality and performance criteria, making them suitable for critical applications.

Applications of HASTELLOY® X Seamless Pipe

HASTELLOY® X seamless pipes are critical components in industries requiring high-temperature strength and corrosion resistance. The following table highlights key applications.

| Industry | Applications |

|---|---|

| Aerospace | Gas turbine combustion zone piping, transition ducts, combustor cans, afterburner piping |

| Chemical Processing | Heat exchanger tubing, reaction vessel piping, pyrolysis tubing |

| Petrochemical | Refinery piping, sulfur recovery units, flare stack piping |

| Power Generation | Boiler tubes, superheater tubes, flue gas desulfurization systems |

| Industrial Furnaces | Radiant tubes, furnace piping, heat treatment equipment |

Detailed Applications:

- Aerospace: Seamless HASTELLOY® X pipes are used in gas turbine engines for combustion zone piping, such as transition ducts and combustor cans, where they withstand temperatures up to 2200°F (1200°C) and resist thermal fatigue. Afterburner piping benefits from the alloy’s oxidation resistance.

- Chemical Processing: The alloy’s resistance to oxidizing and reducing environments makes it ideal for heat exchanger tubing and reaction vessel piping handling acids and chlorides. Pyrolysis tubing benefits from its high-temperature stability.

- Petrochemical: Seamless pipes in refinery systems and sulfur recovery units resist corrosive gases like H2S, while flare stack piping handles high temperatures.

- Power Generation: Boiler and superheater tubes in power plants leverage the alloy’s strength and resistance to flue gas corrosion.

- Industrial Furnaces: Radiant tubes and furnace piping endure oxidizing and neutral atmospheres, with proven durability after 8,700 hours at 2150°F (1177°C).

Chemical Composition of HASTELLOY® X Alloy

The chemical composition of HASTELLOY® X is optimized for high-temperature strength and corrosion resistance. The following table details the composition.

| Element | Weight % |

|---|---|

| Nickel (Ni) | Balance (47–52%) |

| Chromium (Cr) | 20.5–23.0 |

| Iron (Fe) | 17.0–20.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Cobalt (Co) | 0.5–2.5 |

| Tungsten (W) | 0.2–1.0 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Carbon (C) | 0.05–0.15 |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Aluminum (Al) | 0.5 max |

| Titanium (Ti) | 0.15 max |

| Boron (B) | 0.008 max |

Role of Key Elements:

- Nickel: Provides corrosion resistance and high-temperature stability.

- Chromium: Enhances oxidation resistance with a protective oxide layer.

- Molybdenum: Improves pitting and crevice corrosion resistance.

- Iron: Balances strength and cost.

- Cobalt and Tungsten: Boost high-temperature strength and creep resistance.

Physical Properties of HASTELLOY® X Alloy

The physical properties of HASTELLOY® X ensure its suitability for seamless pipe applications. The following table summarizes key properties.

| Property | Value |

|---|---|

| Density | 8.22 g/cm³ (0.297 lb/in³) |

| Melting Range | 2300–2470°F (1260–1355°C) |

| Thermal Conductivity | 11.6 W/m·K at 100°C (8.0 BTU/ft·h·°F) |

| Specific Heat Capacity | 486 J/kg·K at 20°C (0.116 BTU/lb·°F) |

| Electrical Resistivity | 1.18 µΩ·m at 20°C |

| Coefficient of Thermal Expansion | 13.3 µm/m·°C at 20–1000°C (7.4 µin/in·°F) |

| Modulus of Elasticity | 205 GPa (29.7 × 10⁶ psi) at 20°C |

These properties support the alloy’s use in high-temperature piping systems, with low thermal expansion reducing stress during thermal cycling.

Mechanical Properties of HASTELLOY® X Alloy

The mechanical properties of HASTELLOY® X ensure reliability under high stress and temperature. The following table summarizes key properties in the annealed condition.

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 725 MPa (105 ksi) min |

| Yield Strength (0.2% Offset) | 310 MPa (45 ksi) min |

| Elongation | 35% min |

| Hardness | 241 HB max (Brinell) |

| Creep Strength | 48 MPa at 1500°F (816°C) for 10,000 hours |

| Fatigue Strength | ~300 MPa at 10⁷ cycles (room temperature) |

Temperature-Dependent Properties (Approximate):

| Temperature | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| 20°C (68°F) | 755 MPa (110 ksi) | 345 MPa (50 ksi) | 40% |

| 1000°C (1832°F) | 290 MPa (42 ksi) | 165 MPa (24 ksi) | 50% |

These properties ensure seamless pipes withstand high-pressure and cyclic loading in extreme environments.

Fabrication of HASTELLOY® X Seamless Pipe

HASTELLOY® X seamless pipes are manufactured with excellent forming and welding characteristics. The alloy can be hot-worked at 2150°F (1177°C) to ensure uniform heating, enabling seamless pipe production. Cold-working is also feasible due to the alloy’s ductility, allowing for precise dimensional control.

Welding for seamless pipe integration or repairs supports multiple techniques:

- GTAW (TIG): Preferred for high-quality welds in aerospace piping.

- GMAW (MIG): Suitable for rapid welding in industrial settings.

- SMAW: Offers flexibility for field repairs.

- Resistance Welding: Used for specialized joints.

Use matching filler metals and avoid submerged arc welding to prevent cracking. Post-fabrication annealing and rapid cooling restore optimal properties.

Heat Treatment

HASTELLOY® X seamless pipes are supplied in the solution heat-treated condition, annealed at 2150°F (1177°C) and rapidly cooled to enhance corrosion resistance and ductility. Bright annealed pipes are cooled in a hydrogen atmosphere to maintain surface quality. Annealing below 2150°F may cause secondary phase precipitation, reducing strength and ductility.

HASTELLOY® X Seamless Pipe FAQs

1. What makes HASTELLOY® X seamless pipes suitable for high-temperature applications?

The alloy’s high nickel, chromium, and molybdenum content ensures oxidation resistance and strength up to 2200°F (1200°C), ideal for gas turbines and furnaces.

2. How do ASTM B622 and ASTM B829 standards apply?

ASTM B622 specifies seamless pipe dimensions and properties, while ASTM B829 outlines general requirements like testing and tolerances, ensuring quality.

3. Can HASTELLOY® X seamless pipes be welded?

Yes, using GTAW, GMAW, SMAW, or resistance welding with matching filler metals. Avoid submerged arc welding to prevent hot cracking.

4. What industries use HASTELLOY® X seamless pipes?

Aerospace, chemical processing, petrochemical, power generation, and industrial furnaces rely on these pipes for high-temperature and corrosive environments.

5. How does HASTELLOY® X compare to Inconel® 718 for seamless pipes?

HASTELLOY® X offers better oxidation resistance above 1800°F and superior formability, while Inconel® 718 provides higher strength at intermediate temperatures.

6. What testing is performed on HASTELLOY® X seamless pipes?

Hydrostatic, eddy current, flattening, flaring, and tensile tests ensure compliance with ASTM/ASME standards.

7. Where can I source HASTELLOY® X seamless pipes?

Suppliers include abtersteel.com

Key Properties Relevant to Machining

- High Temperature Strength: Maintains strength up to 1500°F (816°C) and oxidation resistance up to 2200°F (1204°C).

- Work Hardening: Rapidly hardens during machining, requiring sharp tools and rigid setups to avoid surface glazing.

- Corrosion Resistance: Resists carburization, nitriding, and stress-corrosion cracking, making it ideal for aerospace, gas turbines, and chemical processing.

- Machinability Rating: Approximately 18% compared to 1112 steel, similar to other nickel-based superalloys like Inconel 625.

Machining Recommendations

- Tool Selection:

- Carbide Tools: Use positive-rake, sharp carbide inserts (e.g., CNMG or SNMG styles, grades like Kennametal KC935, SECO TM4000, or Sandvik GC1015).

- Ceramic Tools: Whisker-reinforced ceramics (e.g., Sandvik 670 or Kennametal KY4300) for roughing forged surfaces at higher speeds (up to 150 SFM).

- Avoid brazed carbide due to insufficient edge strength.

- Cutting Parameters:

- Speed: Low cutting speeds are critical. Start at 45–65 SFM (surface feet/minute) for carbide tools; up to 125–150 SFM for ceramics.

- Feed Rate: 0.005–0.007 inches/rev for turning to prevent work hardening. Avoid peck drilling; maintain steady feeds.

- Depth of Cut: For roughing, use 0.080 inches (linear); for finishing, remove the final 1 mm with smaller inserts.

- Coolant:

- Use high-pressure coolant (HPC) with carbide tools to manage heat and chip evacuation.

- Machine dry with ceramic tools to avoid thermal shock.

- Sulfur-based cutting fluids are recommended but must be removed before heat treatment or high-temperature service.

- Toolpath and Setup:

- Dynamic Toolpaths: Use trochoidal paths with light radial stepovers to maintain constant chip loads and leverage chip-thinning.

- Rigid Setup: Ensure rigid machine tools with high horsepower to prevent vibration and work hardening.

- Avoid burying tools in corners to prevent tool failure.

- Tool Geometry:

- Single-point tungsten carbide tools: 8–10° side-rake angle, 5–8° back-rake angle, 5–7° relief angle.

- Use positive, sharp cutting edges designed for superalloys or austenitic stainless steel.

Conclusion

HASTELLOY® X alloy seamless pipes, compliant with ASTM B622, ASTM B829, ASME SB622, and ASME SB829, are engineered for exceptional performance in high-temperature and corrosive environments. Their high-temperature strength, oxidation resistance, and fabricability make them indispensable for aerospace, chemical processing, and industrial furnace applications. With rigorous standards, robust mechanical properties, and versatile fabrication options, these pipes ensure reliability and longevity.

You must be logged in to post a comment.