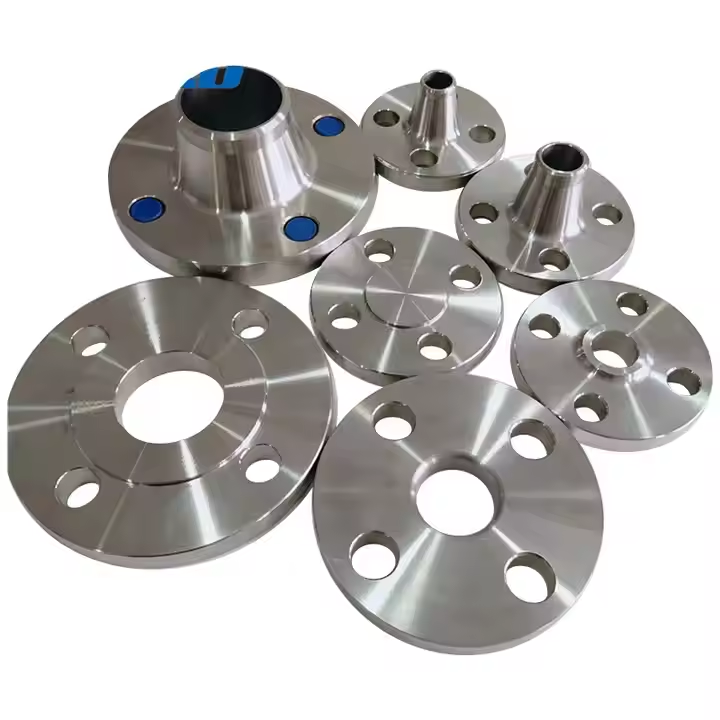

Bebibir ASTM A182 F316 lwn F316L

ASTM A182 adalah spesifikasi standard untuk aloi palsu dan rolled dan bebibir paip keluli tahan karat, kelengkapan palsu, dan injap dan bahagian untuk perkhidmatan suhu tinggi. Dalam spesifikasi ini, Dua gred yang biasa digunakan ialah F316 dan F316L, kedua -duanya adalah varian keluli tahan karat austenit.

Komposisi kimia

Perbezaan utama antara F316 dan F316L adalah kandungan karbon:

| unsur | F316 (% maks) | F316L (% maks) |

|---|---|---|

| Karbon (C) | 0.08 | 0.03 |

| Mangan (MN) | 2.00 | 2.00 |

| Fosforus (P) | 0.045 | 0.045 |

| Sulfur (S) | 0.030 | 0.030 |

| Silikon (Si) | 1.00 | 1.00 |

| Kromium (Cr) | 16.00-18.00 | 16.00-18.00 |

| Nikel (Ni) | 10.00-14.00 | 10.00-14.00 |

| Molibdenum (Mo) | 2.00-3.00 | 2.00-3.00 |

| Nitrogen (N) | 0.10 | 0.10 |

Perbezaan utama

- Kandungan karbon:

- F316: Kandungan karbon yang lebih tinggi (selewat-lewatnya 0.08%) berbanding dengan F316L.

- F316L: Kandungan karbon yang lebih rendah (selewat-lewatnya 0.03%), yang mengurangkan risiko pemendakan karbida semasa kimpalan.

- Kebolehkimpalan:

- F316: Kandungan karbon yang lebih tinggi boleh menyebabkan pemendakan karbida, yang boleh menyebabkan kakisan intergranular di kawasan yang dikimpal.

- F316L: Kandungan karbon rendah meminimumkan risiko pemendakan karbida, menjadikannya lebih sesuai untuk aplikasi kimpalan.

- Sifat mekanikal:

- Kedua -dua gred mempunyai sifat mekanikal yang serupa, Tetapi F316 mungkin mempunyai kekuatan sedikit lebih tinggi kerana kandungan karbon yang lebih tinggi.

Aplikasi

- F316: Sesuai untuk aplikasi suhu tinggi dan tekanan tinggi di mana kimpalan tidak menjadi perhatian.

- F316L: Lebih disukai untuk aplikasi yang memerlukan kimpalan yang luas, seperti sistem paip, kereta kebal, dan penukar haba, disebabkan oleh risiko kakisan intergranular yang lebih rendah.

Tekanan yang dibenarkan dalam ASME B31.3 Proses Piping

ASME B31.3 adalah Persatuan Jurutera Mekanikal Amerika’ standard untuk paip proses, memperincikan reka bentuk, bahan, fabrikasi, perhimpunan, pemeriksaan, dan ujian sistem paip. Tekanan yang dibenarkan untuk bahan dalam ASME B31.3 ditentukan berdasarkan suhu dan sifat bahan.

Tekanan yang dibenarkan untuk F316 dan F316L

Nilai tegasan yang dibenarkan untuk bebibir keluli tahan karat F316 dan F316L (Kedua -duanya mempunyai sifat serupa) Pada suhu yang berbeza diberikan dalam ASME B31.3. Berikut adalah nilai tekanan yang dibenarkan untuk F316 dan F316L pada pelbagai suhu:

| suhu (° C) | Tekanan yang dibenarkan (MPa) |

|---|---|

| 20 | 138 |

| 50 | 138 |

| 100 | 138 |

| 150 | 138 |

| 200 | 124 |

| 250 | 110 |

| 300 | 103 |

| 350 | 93 |

| 400 | 83 |

| 450 | 69 |

Nota:

- Julat suhu: Apabila suhu meningkat, Tekanan yang dibenarkan berkurangan disebabkan oleh pengurangan kekuatan bahan pada suhu tinggi.

- Faktor keselamatan: Nilai tekanan yang dibenarkan menggabungkan faktor keselamatan untuk memastikan bahan dapat mengendalikan tekanan yang ditentukan tanpa kegagalan.

Kesimpulan

Semasa memilih antara bebibir ASTM A182 F316 dan F316L, Pertimbangkan keperluan kimpalan aplikasi dan risiko kakisan intergranular. F316L biasanya disukai untuk aplikasi yang dikimpal kerana kandungan karbon yang lebih rendah, yang mengurangkan risiko pemendakan karbida. Untuk tekanan yang dibenarkan dalam paip proses, Rujuk kepada ASME B31.3, yang memberikan nilai tekanan yang bergantung kepada suhu untuk memastikan operasi sistem paip yang selamat dan boleh dipercayai.

anda mesti log masuk untuk menghantar komen.