Adakah lebih penting than untuk mengepam konkrit siap campur. Terutamanya bagi projek-projek terikat tarikh akhir, menyampaikan paip mestilah tidak gagal.

Satu lapisan ST52 paip akan Haus dalam jangka masa yang singkat. Ini menyebabkan kos yang tinggi bagi penyedia perkhidmatan dalam industri konkrit siap campur kerana masa henti yang disebabkan oleh pembaikan, Perkhidmatan / kerja-kerja penyenggaraan atau penggantian komponen.

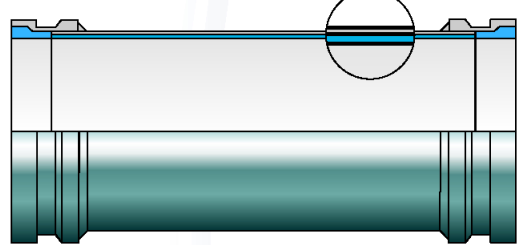

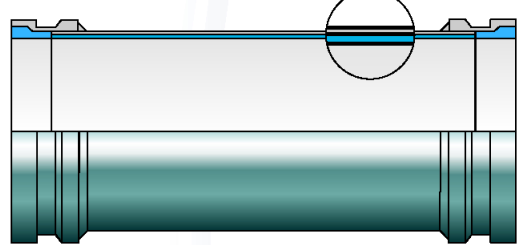

CZPPCO have developed and produced conveying pipes, siku dan bahagian talian penghantaran khas untuk dipasang di trak pam konkrit, trak pam konkrit mixers atau konkrit yang mengedarkan terhadap sejak 1998. The two-layer CZPPCO TWIN PIPES achieve a service life, which is significantly longer than ST52 pipes.

Product Specifications Model Description:

| Nama | struktur | Spesifikasi | Berat badan | Masa hidup | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Tunggal | DN125*3000mm | 48kilo | 6000 – 8000 | ≥45 | ≥27 | 36 Bar |

| Economic wear resistant pipe | Tunggal | DN125*3000mm | 45kilo | 18000 – 22000 | ≥47 | ≥28 | 93 Bar |

| Construction wear resistant pipe | Tunggal | DN125*3000mm | 45kilo | 20000 – 25000 | ≥47 | ≥28 | 93 Bar |

| Diamondwear resistant pipe | Tunggal | DN125*3000mm | 44kilo | 25000 – 35000 | ≥47 | ≥38 | 93 Bar |

| W12-5 wear resistant pipe | Katil Kembar | DN125*3000mm | 43kilo | 50000 – 60000 | ≥ 42 | ≥25 | 59 Bar |

| W12-8 wear resistant pipe | Katil Kembar | DN125*3000mm | 43kilo | 60000 – 80000 | ≥ 43 | ≥25 | 59 Bar |

| GX350-1 wear resistant pipe | Katil Kembar | DN125*3000mm | 44kilo | 80000 – 100000 | – | – | 34 Bar |

| GX350-2 wear resistant pipe | Katil Kembar | DN125*3000mm | 68kilo | 120000 – 150000 | – | – | 76 Bar |

The special hardening process and high-quality welding process ensure that CZPPpipes achieve a service life, which is many times longer than that of commonly available ST52 pipes with the same wall thickness. Boom pipes shall not exceed the specified weight in order to ensure that the stability of the machine is not endangered.

Our pipes are checked for their pressure resistance at regular intervals. The hardness of TWIN PIPE pipes is constant over the entire pipe length so that service intervals can be scheduled more easily. All of our products are manufactured subject to the pump manufacturers’ spesifikasi.

Today, CZPPconveying pipes are used globally.

All CZPPpipes are manufactured in accordance with the weight specifications by concrete pump manufacturers. Conveying pipes for booms are available in two different quality levels. We recommend that you use the CZPP900 XL pipe where you get extreme wear e.g. behind an 10-45° elbow. Those pipes have an extended inlet weld collar to compensate the wear.

| Bahan

Inlet Outlet |

Double layer, hardened inner pipe

Big Mouth weld collar, hardened inner ring Big Mouth weld collar, hardened inner ring |

||

| Kekerasan (acc. Rockwell) | Up to 63 HRC | ||

| Nominal diameter (DN) | [mm] | DN 100 | DN 125 |

| Weld collar size | [inci] | 4,5″ SK | 5,5″ SK |

| ketebalan dinding | [mm] | 2,0 + 2,0 | 2,0 + 2,0 |

| (Inside and outside wall) | 2,5 + 2,0 | ||

| Panjang | [mm] | 100-6000 | |

| Tekanan kerja (P) | [Bar] | 85 | |

| Service life factor*

* Compared with commonly a’ |

5

/ailable ST5 |

2 paip. Medium c | Concrete. |

concrete pump wear resistant pipe

anda mesti log masuk untuk menghantar komen.