ASME B16.25 Коліно для стикового зварювання

вступ

ASME B16.25 is a standard that covers the preparation of butt-welding ends of piping components to make a welded joint. Цей стандарт має вирішальне значення для забезпечення належного монтажу та зварювання компонентів трубопроводів, що забезпечує надійні та герметичні з’єднання. Butt weld elbows are a common type of fitting covered under this standard, used to change the direction of flow in a piping system by 45°, 90°, or other angles.

Types of Butt Weld Elbows

1. 45-Лікоть ступеня

The 45-degree elbow changes the direction of the flow by 45°. It is commonly used in systems where a smooth change in direction is needed without causing turbulence.

2. 90-Лікоть ступеня

The 90-degree elbow changes the direction of the flow by 90°. It is the most commonly used type of elbow in piping systems, ideal for making sharp turns.

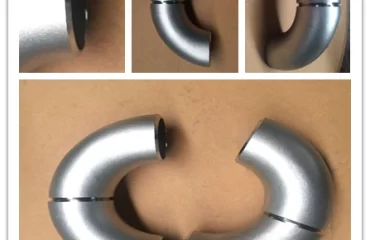

3. 180-Лікоть ступеня

The 180-degree elbow is used to change the direction of flow by 180°, effectively reversing the flow direction. This type is less common but is used in specific situations where a U-turn in the piping is required.

Specifications and Dimensions

1. Номінальний розмір труби (NPS)

ASME B16.25 covers a wide range of nominal pipe sizes (NPS), typically from 1/2 дюйм до 48 дюймів. The size of the elbow correlates with the size of the pipe it will be welded to.

2. Товщина стінки

The wall thickness of butt weld elbows is specified by the schedule number (напр., SCH 10, SCH 40, SCH 80). The schedule number indicates the thickness of the pipe wall and, отже, the elbow’s wall.

3. Radius of Curvature

There are two main types of elbow curvature:

- Короткий радіус (SR): The radius of curvature is equal to the nominal pipe size (1D).

- Довгий радіус (LR): Радіус кривизни становить 1.5 разів більше номінального розміру труби (1.5D). Long radius elbows are commonly used because they cause less pressure drop and flow disruption.

4. End Preparation

The ends of butt weld elbows are prepared according to ASME B16.25 to ensure proper welding. This preparation typically involves beveling the ends of the elbow to facilitate the welding process.

Вибір матеріалу

Butt weld elbows are manufactured from various materials to suit different applications and environments. Загальні матеріали включають:

- Вуглецева сталь: Suitable for general-purpose applications.

- Нержавіюча сталь: Offers excellent corrosion resistance and is used in chemical, pharmaceutical, and food industries.

- Легована сталь: Used in high-pressure and high-temperature environments.

- Дуплекс з нержавіючої сталі: Combines the properties of austenitic and ferritic stainless steels, offering high strength and excellent resistance to stress corrosion cracking.

виробничий процес

1. ковальсько

Butt weld elbows are often manufactured using the forging process, which involves shaping the metal using compressive forces. This process enhances the mechanical properties and grain structure of the material.

2. Формування

In the forming process, the metal is bent or shaped into the required elbow configuration. This can be done using methods such as hot forming or cold forming, depending on the material and specifications.

3. Термічна обробка

Після формування, the elbows may undergo heat treatment processes like annealing or normalizing to relieve internal stresses and enhance mechanical properties.

4. Механічна обробка

The ends of the elbows are machined to ensure they meet the required dimensions and tolerances specified by ASME B16.25.

5. Перевірка та тестування

Quality control measures such as dimensional inspection, non-destructive testing (НК), and pressure testing are conducted to ensure the elbows meet the required standards and specifications.

Додатки

Butt weld elbows are used in various industries, в тому числі:

- Нафта і газ: For transporting crude oil, природний газ, and refined products.

- Хімічна обробка: In systems handling corrosive chemicals and high-temperature fluids.

- Генерація електроенергії: In high-pressure and high-temperature steam lines.

- Очищення води: For conveying water and wastewater in treatment plants.

- Pharmaceuticals: In sanitary piping systems requiring high corrosion resistance and cleanliness.

Installation and Welding

1. Підготовка

Proper preparation is essential for successful welding. This includes cleaning the pipe and elbow ends, aligning the components, and ensuring the correct fit-up.

2. Welding Techniques

Common welding techniques for butt weld elbows include:

- Tungsten Inert Gas (TIG) зварювання: Offers high precision and quality, suitable for thin-walled and critical applications.

- Metal Inert Gas (МІГ) зварювання: Provides faster welding speeds and is suitable for thicker sections.

- Дугове зварювання в екранованому металі (SMAW): Versatile and widely used, especially in field applications.

3. Post-Weld Inspection

Після зварювання, the joints are inspected using methods such as radiographic testing (RT) or ultrasonic testing (UT) to ensure weld integrity and detect any defects.

Future Trends and Innovations

The landscape of manufacturing and application for ASME B16.25 butt weld elbows is poised for significant advancements. These trends and innovations are driven by the need for enhanced performance, стійкість, and integration with modern manufacturing technologies.

Advanced Materials

1. High-Performance Alloys

Advancements in metallurgy are leading to the development of high-performance alloys that offer superior strength, стійкість до корозії, і довговічність.

- Superalloys: Nickel-based superalloys are being developed for high-temperature and high-stress applications, such as those found in aerospace and power generation.

- Titanium Alloys: Known for their high strength-to-weight ratio and corrosion resistance, titanium alloys are becoming more prevalent in critical applications.

2. Composite Materials

The use of composite materials in piping systems is emerging, combining metals with other materials like ceramics or polymers to enhance properties such as thermal resistance and weight reduction.

Адитивне виробництво (3D Друк)

Виробництво добавок is revolutionizing the production of complex piping components, including butt weld elbows.

- Custom Designs: 3D printing enables the creation of custom, complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

- Rapid Prototyping: Engineers can quickly prototype and test new designs, reducing development time and costs.

- Material Efficiency: Additive manufacturing minimizes material waste, promoting sustainability.

Smart Manufacturing and Industry 4.0

Промисловість 4.0 principles, including IoT (Internet of Things), big data, and AI (Artificial Intelligence), are transforming the manufacturing landscape.

1. Predictive Maintenance

- Sensors and Monitoring: Real-time monitoring of equipment and processes using sensors helps predict failures and schedule maintenance before breakdowns occur.

- Data Analytics: Big data analytics can optimize production processes, reducing downtime and improving efficiency.

2. Automation and Robotics

- Robotic Welding: Automated welding systems ensure consistent quality and precision, reducing human error and increasing throughput.

- Smart Factories: Integrated systems and robotics enhance flexibility and adaptability in manufacturing processes.

Environmental Sustainability

Sustainability is becoming a key focus in the manufacturing of piping components.

1. Recycling and Circular Economy

- Material Recycling: Emphasizing the recycling of metals to reduce raw material consumption and environmental impact.

- Circular Economy: Designing products for easier disassembly and recycling at the end of their life cycle.

2. Eco-Friendly Processes

- Зелене виробництво: Implementing processes that minimize energy consumption and emissions, such as using renewable energy sources.

- Low-Impact Coatings: Developing coatings that protect components without harmful environmental effects.

Advanced Coating Technologies

Innovations in coating technologies are enhancing the performance and lifespan of butt weld elbows.

- Nanocoatings: Ultra-thin coatings that provide superior corrosion resistance, wear resistance, and hydrophobic properties.

- Self-Healing Coatings: Coatings that can automatically repair minor damages, extending the service life of components.

Enhanced Inspection and Testing

Improvements in non-destructive testing (НК) methods are ensuring higher quality and reliability.

- Advanced Ultrasonic Testing (AUT): High-resolution imaging techniques for detecting flaws and ensuring weld integrity.

- Phased Array Ultrasonics (ПОСИЛАННЯ): Provides detailed images of welds, allowing for precise defect characterization.

Digital Twins

The concept of digital twins—virtual replicas of physical components—allows for simulation and analysis of performance under various conditions.

- Predictive Analysis: Simulating the behavior of components under different scenarios to predict potential issues and optimize designs.

- Maintenance Optimization: Using digital twins to plan maintenance activities and improve asset management.

Висновок

ASME B16.25 butt weld elbows play a critical role in the reliability and efficiency of piping systems across various industries. Understanding the specifications, матеріалів, manufacturing processes, and installation techniques is essential for selecting and using these components effectively. By adhering to the standards and best practices outlined in ASME B16.25, engineers and technicians can ensure the safety, продуктивність, and longevity of their piping systems.The future of ASME B16.25 butt weld elbows is set to be shaped by advancements in materials, manufacturing technologies, and sustainability practices. By embracing these trends and innovations, the industry can enhance the performance, надійність, and environmental footprint of piping systems, meeting the evolving demands of modern applications.

This comprehensive guide provides a detailed overview of ASME B16.25 butt weld elbows, covering everything from types and specifications to manufacturing processes and applications.This guide provides an insight into the future trends and innovations in the manufacturing and application of ASME B16.25 butt weld elbows, highlighting how emerging technologies and practices are set to transform the industry.

Ви повинні бути увійти в систему щоб залишити коментар.