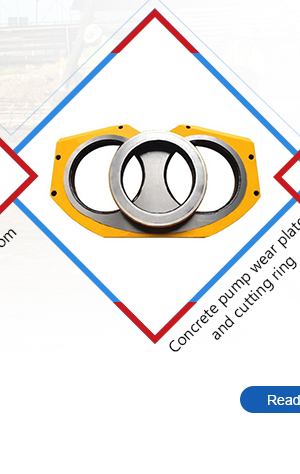

Pump accessories: Wear Plate cutting ring knowledge encyclopedia

Wear Plate is also called wear plate, English: Wear Plate is an important part of concrete pump truck. Shaped like Wear Plate, it is called Wear Plate. At present, the commonly used materials are: (1) high chromium alloy cast iron. (2) Tungsten carbide. (3) Cemented carbide. (4) Alloy ceramics. The cutting ring is also called wear ring, and English Cutting Ring is an important part of concrete pump truck. Shaped like a ring. The working state is a shearing motion, so it is called a cutting ring. At present, the commonly used materials are: (l) high chromium alloy cast iron. (2) Tungsten carbide. (3) Cemented carbide. (4) Alloy ceramics.

The user asks: When using concrete pump, the length can reach 30,000 square meters, while the short one is only a few thousand squares?

Wear Plate and cutting ring have a very long service life. Among them, the service life of the Wear Plate has a service life of 4,000 square meters to 150,000 square meters. What is the reason?

According to the analysis of the use of concrete pump for many years, the reasons for the service life of Wear Plate and cutting ring are as follows.

First, the difference in the concrete pumped at each site. In general, the Wear Plate and the cutting ring have a longer service life when the ratio is reasonable (commercial concrete). Taking the Chongqing area as an example, the construction site uses commercial concrete. The life of the Wear Plate can reach more than 120,000 square meters, and the life of the cutting ring is also between 1.5 and 400,000 square meters.

Second, the difference in pumping conditions at each site. Pumping concrete under high-altitude and long-distance conditions, the Wear Plate and the cutting ring have a shorter life due to their greater back pressure.

Third, the gap between the Wear Plate and the cutting ring also affects the service life. The cutting ring has a large preload and can be pressed against the Wear Plate. The mortar will not enter when pumping. At this time, the Wear of Wear Plate occurs all over the flat and wears more evenly, so its life is longer. The wear of the cutting ring occurs at the edge of the cutting ring. If we can adjust the direction of the cutting ring in time to make the edge wear evenly, the life of the cutting ring will be doubled. When the Wear Plate has a large gap with the cutting ring or the rubber spring ages, the mortar and small aggregate will easily enter between the Wear Plate and the cutting ring under back pressure. Since each working cycle is cut twice with the cutting ring, the Wear Plate is the easiest place to enter the small aggregate, which is easy to cause the Wear Plate to wear away.

Therefore, after working for a certain period of time, the concrete pump truck should train the direction of the cutting ring and tighten the profile nut, which will greatly extend the service life of the Wear Plate and the cutting ring.

You must be logged in to post a comment.