Wear Resistant Concrete Pump Pipe Elbow

45 Degree, 90 Degree Bend Elbow Technology: Concrete pump elbow,bend pipe is quenched and carried out carburizing chemical treatment on the inner wall. So it has high wear resistance.Twin walls elbow the inner layer is made of high hardness wear resistant alloy stll by hear treatment and the outer tube is high toughness and low hardness and low carbon steel,which can guarantee the construction safety.

| Product Name | Concrete Pump bend Elbow |

| Inner characteristic | the inner layer of this concrete pump elbow undergoes heat treatment,and then the rigitiry can reach 62-65HRC. |

| Outer characteristic | the outer layer of the concrete pump elbow possess good toughness properties to protect the inner layer,so the security of the elbow is improved. |

| life | the experiment done abroad shows that the life of our concrete pump elbow can reach 35000-50000cbm,got the customers’ praise |

| Notes: |

Beside the double layer concrete pump elbow,we produce all kinds of concrete pump parts,straight pipe hose flange coupling and so on. |

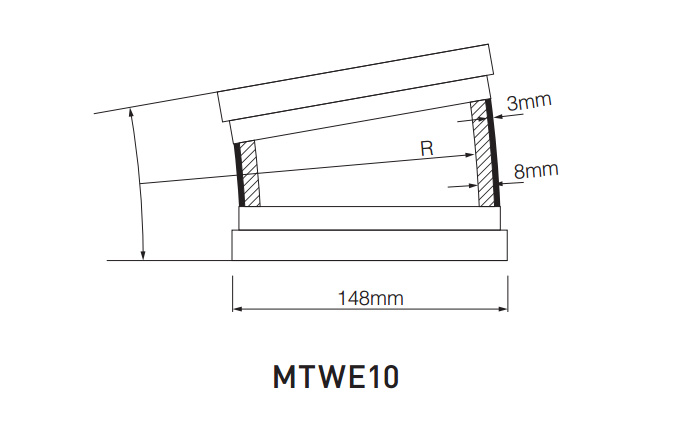

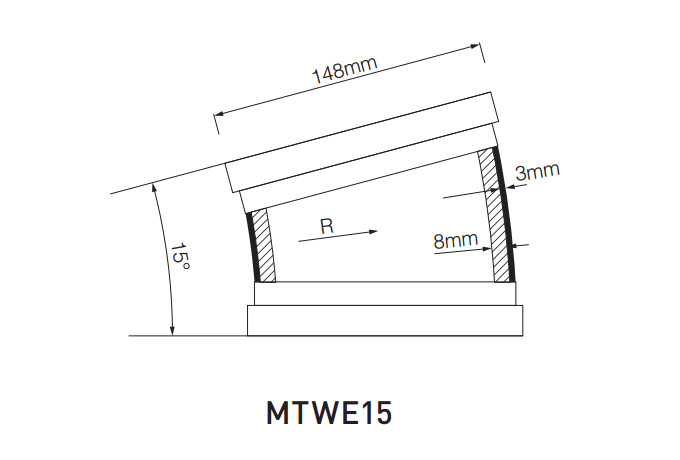

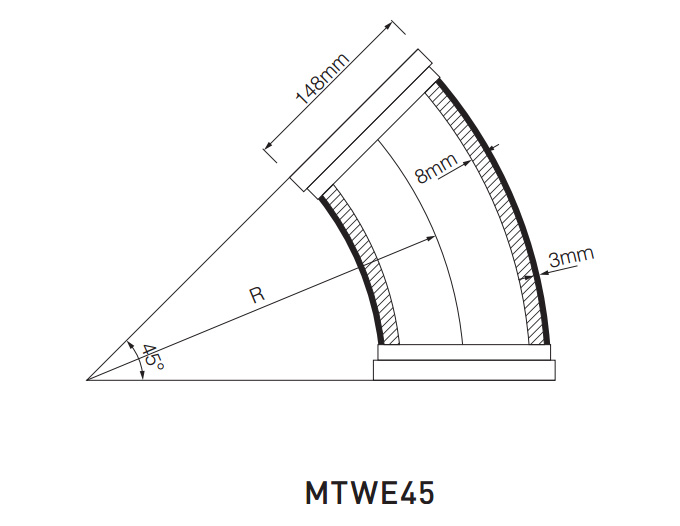

Double Wall Pipe Elbow, 45 Degree, 90 Degree Bend elbow PARAMETERS:

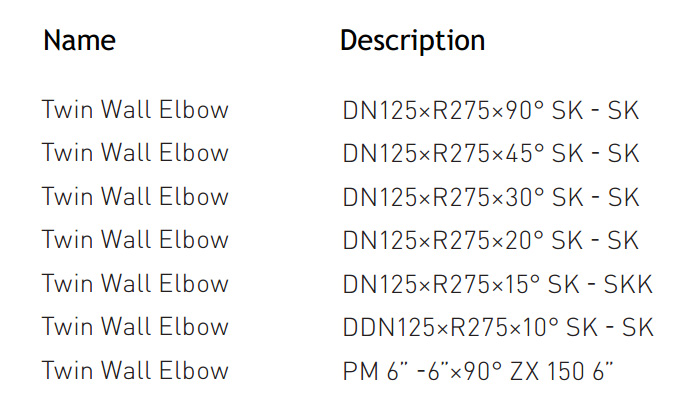

| Name | Description | |

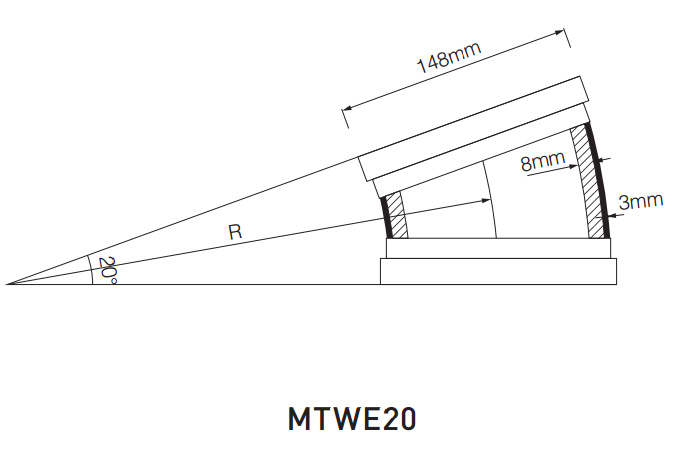

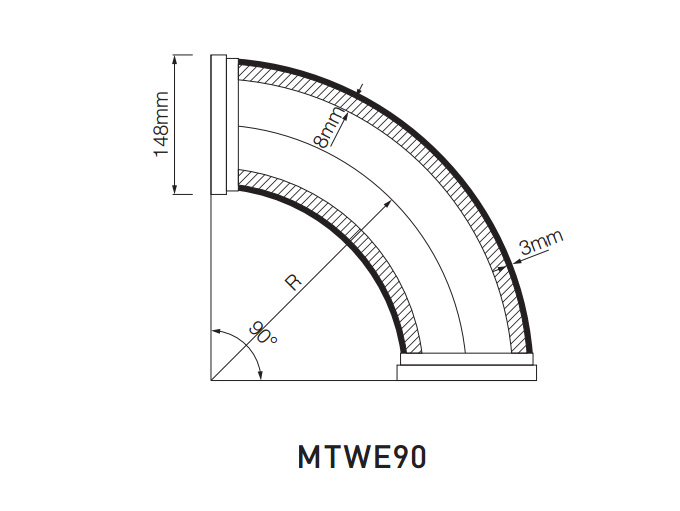

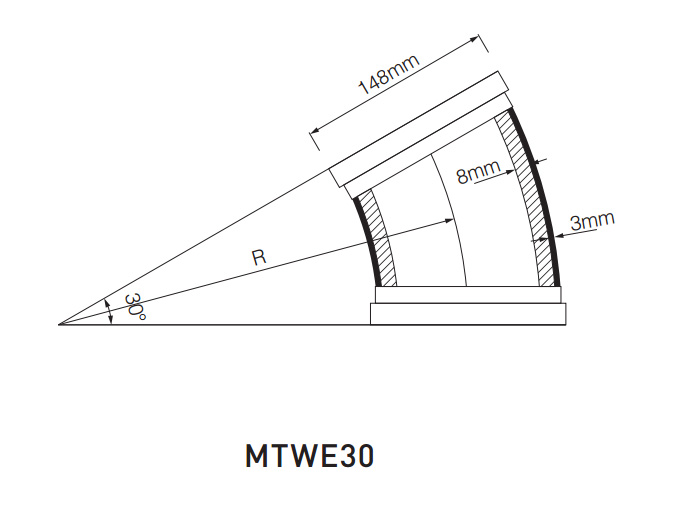

| Twin Wall Pipe | DN125×R275×90° SK – SK (45°/30° /20°/10° available) |

|

| PM 6″ -6″×90° ZX 150 6″ | ||

| Single wall elbow |

DN100×45D/90D ×R500 SK 100 4-1/2″ | |

| DN100×45D/90D ×R1000 SK 100 4-1/2″ | ||

| DN125×15D/ 30D ×R500 SK 125 5-1/2″ | ||

| DN125×45D×R500 5-1/2″ | ||

| DN125×60D/ 90D ×R500 SK 125 5-1/2″ | ||

| DN125×15D ×R1000 SK 125 5-1/2″ (30D/45D/60D/90D available) |

||

| Bend elbow MF 125 5″ |

DN125×15D×R1000 (30D,45D,60D,90D available) |

|

| Bend elbow ZX 125 5″ |

DN125×15D×R1000 (30D,45D,60D,90D available) |

|

| Cast Pipe |

DN125 × R180 / R225 / R260 × 90° | |

| DN125 × R260× 90° +211 | ||

| DN125 × R275 /R340 × 90° | ||

| DN125 × R275× 45° | ||

| DN125 × R275× 45°+170 | ||

| DN125 × R275× 45°+411 | ||

| DN125 × R240 / R275 / R315 × 30° | ||

| DN125 × R385× 29° | ||

| DN125 × R275× 15° | ||

| DN125 × R240× 15° | ||

Concrete placing boom 90-degree elbow this product by the special material of steel pipe, through the inner wall quenching, carburizing chemical treatment, flange liner hardness of 58-60 degrees, pipe service life increased 3-5 times, in order to save the user time and cost, free from the trouble of frequent pipe change, improve production efficiency.

The company produces a complete set of wear-resistant pipe fittings weighing low (weighing is the necessary guarantee of the normal operation of the car pump) high ash delivery side, is the ideal pump car piping.

Company Quality Inspection Department of the company’s products for the geometrical size of 100% full inspection (1 wear-resistant tube tape 2 caliper 3 platform elbow caliper)

Concrete placing boom with 90 degree elbow hardness inspection:

Test of hardness of straight tube and bend Tublo

Pressure test:

In the production process, the company quality Inspection Department personnel to do destructive sampling

1 Quality Inspection Department personnel to carry out mn13-4 bending pipe pressure destructive sampling

2 The company quality Inspection department personnel to wear straight pipe pressure destructive sampling

Water pressure test:

1 Quality Inspection Department personnel for abrasion-resistant straight pipe of the water pressure destructive sampling

2 Quality Inspection Department personnel to carry out mn13-4 water pressure destructive sampling

Magnetic particle flaw detection of welding mouth:

QC Department personnel to the product welded joints 100% magnetic particle flaw detection

X-ray flaw detection and ultrasonic flaw detection of casting bend pipe

Company QC personnel of the export casting pipe 100%x optical flaw detection and ultrasonic testing team.

90-degree elbow technical equipment for concrete placing machines:

1. Sawing machine accurate blanking effective control in the straight tube geometric size error ≤0.5mm, and independent research and development of rotary sand cutting equipment to overcome the tube hardening after the thermal impact of the material and oblique mouth problem.

2. The company adopts the imported UHF quenching equipment to ensure the microstructure and hardness of the wear-resistant tube martensite and HRC60, and in 06 and days high group joint design production of cone-pipe push equipment to fill the domestic cone tube if pushed to the process of blank.

3. The company uses automatic 6-position wax-casting machine and aerospace aluminum abrasive materials, improve production efficiency and product size accuracy of the full inspection.

You must be logged in to post a comment.