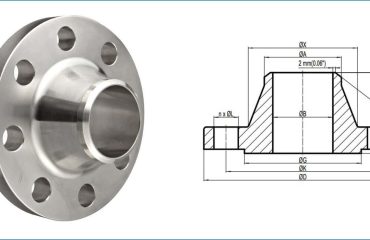

analysis of F53/UNS S32750 super duplex stainless steel flanges:

Introduction

As applications in oil/gas processing and seawater service move to ever more corrosive and extreme conditions, duplex stainless steels reach their tolerance limits. Super duplex grades like UNS S32750 standardized in F53 balances push these boundaries, offering the highest strengths, corrosion resistance and cathodic protection in the duplex family. This report analyzes S32750 flanges through evaluating composition, microstructure, mechanical properties and standards governing their fabrication to ensure flawless performance under demanding services.

Chemical Composition and Microstructure

S32750 contains 28-30.5% chromium and 4-6% nickel along with 3-4% molybdenum imparting strengthened pitting/crevice resistance compared to standard duplex alloys. Higher amounts of tungsten (1.5-2.5%) and nitrogen (0.2-0.4%) promote delta ferrite formation balancing the microstructure at 50-60% austenite islands within a ferritic matrix. This confers yield strengths to 110 ksi with 30% minimum elongation and fracture toughness exceeding 300 ksi√in. The optimally balanced phases impart synergistic strengths while resisting localized corrosion mechanisms.

Material Standards

Key specifications for S32750 flanges include:

- ASTM A182/ASME SA-182 chemical composition

- ASTM A923 addressing welding consumables tolerance

- NACE MR-0175 covering use in H2S services

- API 650/673 evaluating tank/vessel applications

- ISO 15156 governing corrosion-resistant alloys in oil/gas

Fabrication Practices

Critical heat treatments after casting or forging refine microstructure:

- Solution annealing held 980-1020°C one hour normalizes phases

- Rapid quenching locks microstructure

- Stabilizing treatments 550-720°C manage precipitation

Welding and non-destructive testing protocols ensure structural integrity. Post-weld solutionizing mitigates sensitization risks.

Performance and Reliability

S32750’s dual-phase structure and elevated alloy content provide critical benefits:

- Strengths 50% higher than standard duplex grades

- 5x general corrosion resistance of austenitic alloys

- Threshold pitting potentials 50% above austenitic alloys

- Cathodic protection sustainabilities under -1V vs Ag/AgCl

When combined with meticulous fabrication per specifications, S32750 flanges maintain functions even in highly polluted seawater or sour gas environments at sub-zero temperatures, drastically reducing costs of corrosion failures.

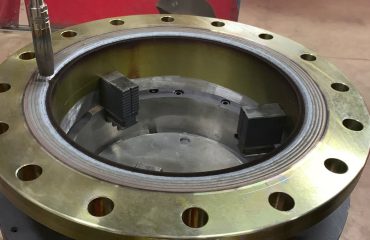

Non-Destructive Examination

Flange condition over decades demands vigilant monitoring:

- Ultra-sonic testing quantifies wall thinning versus minimums

- Magnetic particle screening detects surface/subsurface discontinuities

- CT scans reconstruct internal flaw geometries in 3D

- Hydrotests confirm pressure-containing capability end-of-design-life

Only through such diligent qualification can S32750 flanges assure safety and reliability as critical junctures in offshore pipelines carrying processed fluids.

Conclusion

In summary, S32750 duplex stainless improves on conventional duplex alloys’ attributes, delivering pivotal strengths flanges require withstanding arduous marine and oil/gas applications. Compliant fabrication accompanied by standardized inspection confirms as-new condition throughout service lifetimes. Well into the future, S32750 will continue enabling infrastructure transporting resources from ever deeper reserves.

You must be logged in to post a comment.