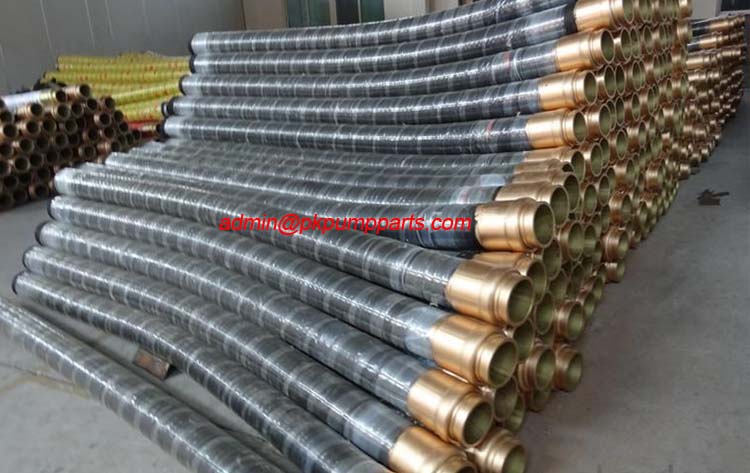

Concrete Pump Rubber Hose designed to handle the pumping of concrete, plaster or grout mixture. All purpose cover provides excellent flexibility and wear resistance to abrasive slurries.

Concrete pump rubber hose production of the basic processes for the processing of rubber, cord and canvas processing, concrete pump rubber hose molding, curing and so on. Different structures and different skeleton of the concrete pump rubber hose, the skeleton of the processing methods and concrete pump rubber hose forming equipment vary.

Coreless molding

Concrete pump rubber hose coreless molding, the equipment is extrusion machine (commonly used screw extruder), the skeleton layer and the outer layer directly in the extrusion of the concrete pump rubber hose on the shape.

The compound is agitated, mixed, plasticized and pressed in the barrel by means of the extrusion screw, and then moved to the direction of the nose, and finally the product of the shape of the extruder is extruded from the mouth, And cold feed two, the former feed through the open mixing machine preheating of the material, which feed not through the hot rubber compound.

Core forming

Concrete pump rubber hose with core forming, refers to the concrete pump rubber hose in the hard core or soft core on the shape, in order to ensure that the concrete pump rubber hose in the vulcanization process in a state of pressure, concrete pump rubber hose in the molding after the package Water cloth (about 10cm wide damp cloth), rope or leaded, and then vulcanized.

notes when using the concrete pump rubber hose

1, concrete pump rubber hose and concrete pump rubber hose assembly of the media temperature under normal circumstances, should not exceed -40 ℃ – +120 ℃, otherwise it will reduce the service life.

2, concrete pump rubber hose and concrete pump rubber hose assembly should be handled carefully, should not be dragged on sharp and rough surface, should not bend and flatten.

3, large diameter concrete pump rubber hose assembly should be kept clean, the internal should be washed clean (especially the acid tubing, spray pipe, mortar). To prevent foreign objects into the lumen, hinder the delivery of fluid, damage to equipment.

4, large diameter concrete pump rubber hose assembly should not be less than the minimum bending radius of concrete pump rubber hose to avoid bending or bending near the pipe joints, otherwise it will hinder the hydraulic transmission and transportation of materials or damage to concrete pump Rubber hose assembly.

5, concrete pump rubber hose and concrete pump rubber hose assembly, should not be used in the reverse state.

You must be logged in to post a comment.