The Inner Monologue: The Soul of the P245GH Flange

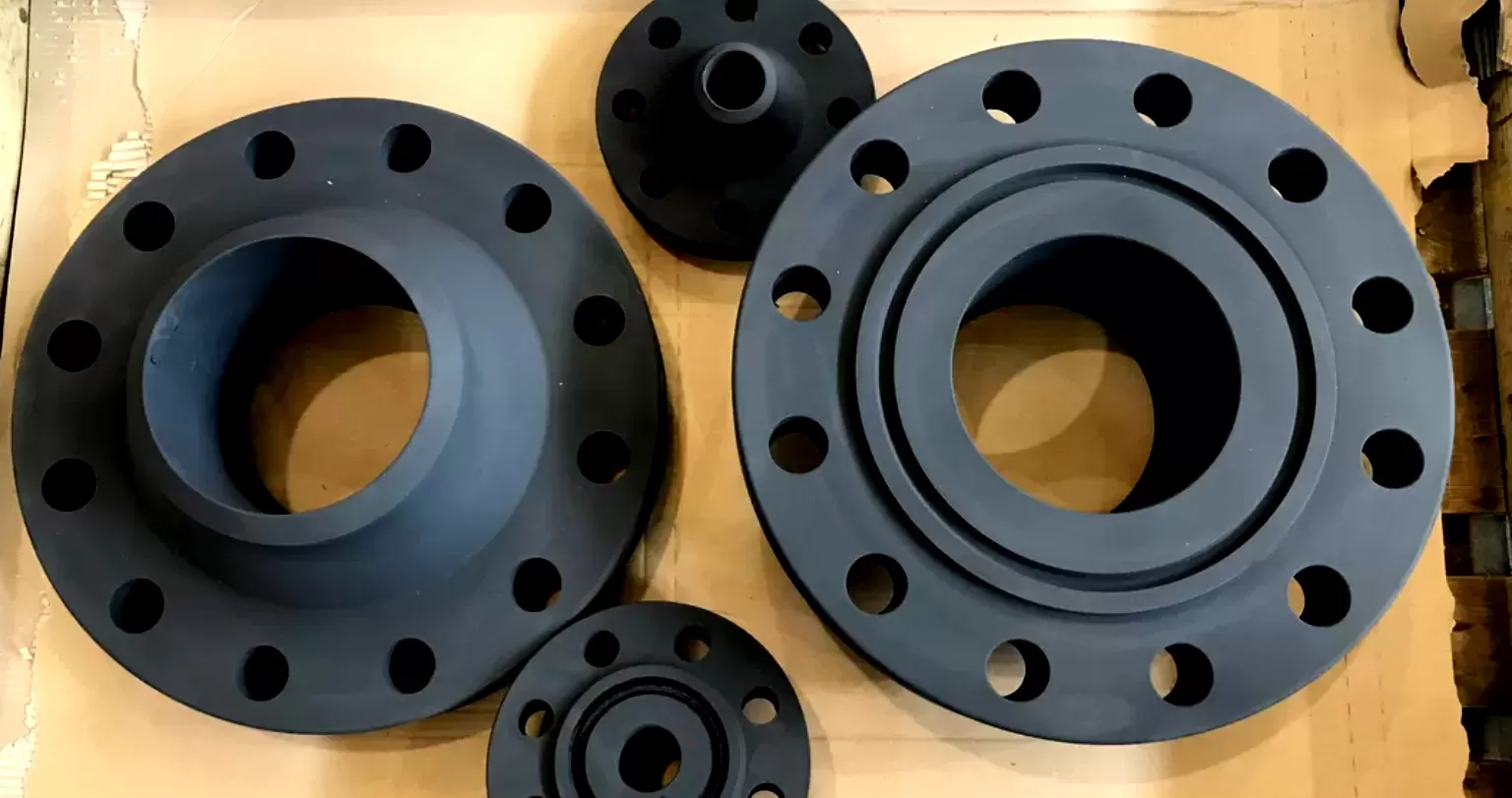

I am contemplating the P245GH carbon steel plate flange—specifically the Slip-On Raised Face (SORF) variant—through the lens of Abtersteel’s manufacturing philosophy. It isn’t merely a disc of metal with holes; it is a critical pressure-retaining component that must reconcile the rigid requirements of EN 10222-2 with the practicalities of field welding. Why P245GH? The ‘P’ denotes pressure, the ‘245’ refers to the minimum yield strength in Megapascals, and the ‘GH’ signifies its aptitude for elevated temperatures. If the carbon is too high, the weld becomes brittle—a death sentence for a flange under PN100 pressure. If it’s too low, we lose the structural “backbone” needed for the SORF design. The pipe slides inside the flange; there are two fillet welds, one internal and one external. This is fundamentally different from a Weld Neck flange. It’s easier to align, but it carries a higher fatigue load at the hub. My mind shifts to the Pressure-Nominal (PN) ratings. From the low-pressure PN06 to the aggressive PN100. This represents a massive shift in flange thickness and bolt-hole diameter. Is it a rolled plate or a forged ring? For P245GH, the fine-grained structure is everything. I also need to consider the “Raised Face” (RF). That 2mm or 5mm protrusion is where the gasket lives. The serrations—the phonographic finish—they must bite into the gasket to prevent a blowout at 100 bar.

Technical Analysis: SORF P245GH Flanges in High-Pressure Service

In the architecture of modern industrial piping, the Slip-On Raised Face (SORF) flange manufactured from P245GH steel stands as a primary intersection of economy and reliability. While complex specialized alloys exist for extreme chemistry, the P245GH carbon steel remains the global workhorse for steam, gas, and liquid transport across the European EN 1092-1 standard landscape. At Abtersteel, the production of these components involves a deep understanding of the metallurgical transition between room temperature and elevated thermal service.

Metallurgical Profile: The P245GH Advantage

P245GH is a non-alloy quality steel intended for pressure purposes. Its uniqueness lies in its “fine-grain” structure, achieved through controlled aluminum killing and specific heat treatment cycles. When we analyze the chemistry, we see a deliberate limitation of Phosphorus (P) and Sulfur (S) to levels below 0.025% and 0.015%, respectively. This cleanliness is vital for the flange’s “Through-Thickness” ductility.

The “GH” suffix is the hallmark of the material’s ability to maintain its yield strength ($Re$) even when the temperature climbs toward $400^\circ\text{C}$. Unlike standard S235JR construction steel, P245GH undergoes a normalizing process ($910^\circ\text{C}$ to $930^\circ\text{C}$) that homogenizes the grain structure, ensuring that when a PN63 or PN100 line experiences thermal expansion, the flange does not succumb to creep or localized deformation.

| Chemical Element | Requirement (EN 10222-2) | Abtersteel Precision Range |

| Carbon (C) | 0.08 – 0.20% | 0.15% (Optimized for Weldability) |

| Silicon (Si) | $\leq$ 0.40% | 0.25% |

| Manganese (Mn) | 0.50 – 1.30% | 1.10% |

| Chromium (Cr) | $\leq$ 0.30% | 0.05% |

| Aluminium (Al) | $\geq$ 0.020% | 0.035% (Grain Refinement) |

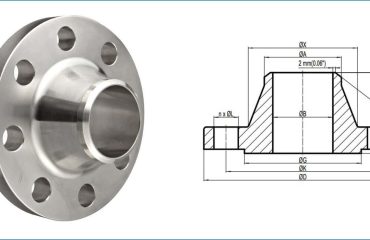

The Engineering of SORF (Slip-On Raised Face)

The SORF design is preferred for many Abtersteel clients due to its lower initial cost and ease of installation. In a SORF configuration, the flange is slipped over the pipe, and the pipe’s end is set back from the flange face by a distance roughly equal to the wall thickness plus 3mm.

The Double Fillet Weld:

A SORF flange requires two welds:

-

An External Fillet Weld: Around the hub of the flange.

-

An Internal Fillet Weld: At the end of the pipe inside the flange bore.

While this makes alignment simpler than a Weld Neck flange (which requires a butt weld), it introduces a stress concentration at the hub. For high-pressure ratings like PN63 and PN100, the thickness of the SORF “plate” portion must be significantly increased to resist the bending moment created by the bolt load against the Raised Face.

Pressure Ratings: From PN06 to PN100

The Pressure Nominal (PN) rating system is a shorthand for the maximum allowable pressure (in bar) at a reference temperature of $20^\circ\text{C}$. As the pressure increases, the physical dimensions of the flange evolve.

For PN06, the flange is relatively thin, often used in low-pressure water treatment or cooling circuits. However, as we move toward PN40 and PN100, the bolt circle diameter and the number of bolts increase to distribute the massive clamping force required to compress the gasket.

Abtersteel’s technical data for P245GH SORF flanges highlights the following dimensional progression (sample for DN100 pipe):

| Pressure Rating | Flange OD (mm) | Thickness (C) (mm) | Bolt Holes (No.) | Bolt Hole Dia (mm) |

| PN10 | 220 | 20 | 8 | 18 |

| PN16 | 220 | 20 | 8 | 18 |

| PN25 | 235 | 24 | 8 | 22 |

| PN40 | 235 | 24 | 8 | 22 |

| PN63 | 250 | 30 | 8 | 26 |

| PN100 | 265 | 40 | 8 | 30 |

Note: In higher PN ratings, the thickness (C) increases significantly to prevent the “cupping” of the flange under high bolt torque.

Sealing Integrity: The Raised Face (RF) Surface Finish

The Raised Face is not merely a flat surface; it is an engineered interface. The standard height for an RF on a P245GH flange is 2mm for ratings up to PN40, and 5mm for PN63 and PN100.

Abtersteel employs a “Stock Finish” on the RF, which consists of a continuous spiral groove. The purpose is to create a “labyrinth” seal. When the bolts are tightened, the gasket material (whether it is graphite, PTFE, or a spiral-wound metallic gasket) is forced into these micro-grooves.

Surface Roughness ($R_a$):

For P245GH flanges, the roughness is typically maintained between 3.2 and 6.3 $\mu$m. If the surface is too smooth (mirror finish), the gasket may “blow out” laterally under pressure. If it is too rough, the fluid may find a leak path through the valleys of the serrations.

Stress and Mechanical Performance

Under high pressure, a SORF flange acts as a cantilever beam. The bolt force is applied at the outer diameter, while the reaction force of the gasket is at the inner diameter. This creates a “Flange Moment.”

For P245GH, the mechanical properties are strictly monitored by Abtersteel to ensure compliance with EN 10222-2:

-

Yield Strength ($R_{eH}$): $\geq 245\text{ MPa}$

-

Tensile Strength ($R_m$): $360 – 480\text{ MPa}$

-

Impact Energy (KV at $-20^\circ\text{C}$): $\geq 27\text{ J}$ (Crucial for preventing brittle fracture during winter start-ups).

The high yield strength of P245GH at $200^\circ\text{C}$ (approximately $185\text{ MPa}$) is what allows Abtersteel to certify these flanges for steam service where standard carbon steels would begin to lose their safety factor.

Quality Assurance at Abtersteel

Every SORF P245GH flange is an exercise in traceability.

-

Heat Number Stamping: Every flange is linked back to the original ladle analysis of the steel.

-

Ultrasonic Testing (UT): For PN63 and PN100 ratings, Abtersteel performs UT on the raw material to ensure no internal laminations exist that could be opened up by the welding process.

-

Visual Inspection: Checking the phonographic finish on the Raised Face for any radial scratches, which are the most common cause of “seepage” leaks.

Part II: Thermal Mechanics, Sealing Integrity, and Installation Dynamics

While the material properties of P245GH provide the structural foundation, the operational success of an Abtersteel SORF flange depends on the management of thermal transients and the physics of the bolted joint.

The Behavior of P245GH under Thermal Cycling

One of the primary reasons for selecting P245GH for PN16 to PN100 services is its resilience to thermal cycling. In power plants or refinery heat exchangers, the temperature rarely stays constant.

When the temperature increases, the bolt and the flange expand at slightly different rates due to their differing masses and potential slight variations in alloy content.

-

The “Creep-Relaxation” Factor: In high-temperature service (above $300^\circ\text{C}$), the P245GH steel experiences a slight relaxation of internal stress. If the material were a standard carbon steel, this relaxation would lead to a loss of bolt tension.

-

The GH Stability: The specific grain-refining elements (Aluminium and Nitrogen) in P245GH stabilize the ferrite matrix, ensuring that the “Elastic Follow-up” of the flange maintains pressure on the gasket even as the system fluctuates.

Pressure-Temperature Ratings (The P-T Rating)

It is a common misconception that a PN40 flange can always handle 40 bar. In reality, as the temperature rises, the allowable pressure drops. This is the Pressure-Temperature Rating defined by EN 1092-1.

For Abtersteel P245GH flanges, the derating curve is a critical piece of data for the design engineer.

| Temperature (∘C) | PN16 (bar) | PN25 (bar) | PN40 (bar) | PN63 (bar) | PN100 (bar) |

| -10 to 50 | 16.0 | 25.0 | 40.0 | 63.0 | 100.0 |

| 100 | 14.8 | 23.2 | 37.1 | 58.5 | 92.8 |

| 200 | 13.3 | 20.8 | 33.3 | 52.5 | 83.3 |

| 300 | 11.0 | 17.2 | 27.6 | 43.5 | 69.0 |

| 400 | 8.0 | 12.5 | 20.0 | 31.5 | 50.0 |

This table illustrates that at $400^\circ\text{C}$, the capacity of the flange is effectively halved. This highlights why the fine-grained P245GH is necessary; a lesser steel would be prohibited from service at these higher temperatures entirely.

The SORF Hub and Weld Geometry

In a Slip-On flange, the “Hub” is the vertical section that extends from the plate. While it is smaller than the hub on a Weld Neck flange, its geometry is vital for distributing the stress from the fillet weld.

Abtersteel’s Design Focus:

-

Bore Tolerance: The internal diameter (Bore) must be precisely machined to be slightly larger than the Pipe OD. If the gap is too large, the internal fillet weld will be excessive, leading to distortion. If it’s too tight, thermal expansion during welding could cause the flange to “seize” on the pipe before it’s in the correct position.

-

The X-Distance: The setback of the pipe from the flange face is critical. If the pipe is too close to the face, the internal weld will interfere with the Raised Face sealing surface. If it is too far, it creates a “dead space” where corrosive fluids can pool and cause Crevice Corrosion.

Gasket Seating and Surface Finish ($R_z$ vs $R_a$)

For the SORF Raised Face, Abtersteel utilizes a specific serrated finish. In the European market, we often discuss this in terms of $R_z$ (mean peak-to-valley height) rather than just $R_a$.

-

Concentric vs. Spiral: While spiral (phonographic) is standard, certain high-vacuum or lethal-service applications (PN63/100) may require concentric grooves. This is because a spiral groove theoretically provides a continuous, albeit microscopic, leak path from the ID to the OD.

-

Sealing Pressure ($Q_{min}$): For a P245GH flange to seal effectively, the bolts must exert enough force to reach the “minimum sealing stress” of the gasket. For a PN100 DN100 flange, this requires a torque that can exceed $600\text{ Nm}$ per bolt, depending on the lubricant used.

The Economic Synergy of SORF and P245GH

From a procurement perspective at Abtersteel, the SORF P245GH flange offers a “middle ground” that is highly efficient:

-

Material Cost: Cheaper than stainless steel (316L) or high-alloy chromes (P91), but vastly more capable than A105 or S235 steel.

-

Labor Cost: Slip-on flanges don’t require the complex “beveling” and precision fit-up of Weld Neck flanges. A welder can fit a SORF flange faster, reducing the “Man-Hours per Joint” metric in large-scale construction.

-

Weight Optimization: Plate flanges are generally lighter than forged weld necks, reducing the overall dead-load on piping supports.

Final Technical Summary

The SORF P245GH flange is the silent guardian of the pressure boundary. Its success is not just in its 245 MPa yield strength, but in its chemical purity and the precision with which the Raised Face is machined.

-

Abtersteel’s P245GH ensures high-temperature creep resistance and excellent weldability.

-

The SORF design provides installation flexibility and alignment ease.

-

The PN ratings allow for a scaled safety approach, ensuring that whether a system is running at 6 bar or 100 bar, the material remains within its elastic limit.

By adhering to the EN 1092-1 standards and maintaining strict control over the normalizing heat treatment, Abtersteel produces a component that reconciles the high-energy demands of the modern refinery with the economic realities of global infrastructure.

The P245GH SORF flange is a masterpiece of European material standards. It provides a robust, weldable, and heat-resistant solution for the backbone of modern industry. By selecting the correct PN rating and ensuring the SORF hub is welded with the precision required for its geometry, engineers can rely on Abtersteel components to provide a leak-free service life exceeding 25 years. Whether it is the low-demand PN06 or the extreme PN100, the P245GH’s fine-grained martensite-free structure is the ultimate guardian of pipeline integrity.

You must be logged in to post a comment.