Carbon Steel Butt Weld Concentric Reducers and Eccentric Reducers: Forging Connections in the Pulse of Industry

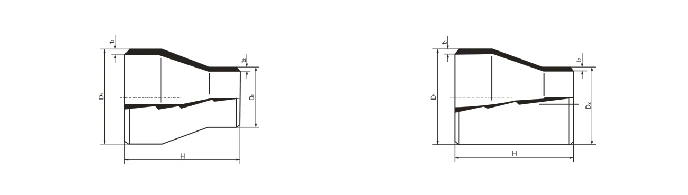

Let us wander first into the heart of what makes a reducer tick, that seamless shift from wide to narrow, where fluid dynamics meet metallurgy’s unyielding hand. In the concentric reducer, the centers align like stars in perfect constellation, the large end’s embrace tapering evenly to the small, preserving a uniform centerline that invites laminar flow with minimal rebellion. This symmetry, so deceptively simple, shines in scenarios where balance reigns—gas lines humming with even pressure, or chemical feeds where turbulence could spell waste or worse. Contrast this with the eccentric kin, where the axis shifts, one side flat as a horizon, the other curved like a secret incline. Here, the design anticipates the mischief of air pockets or sediment traps, tilting the transition to keep solids scoured clean or vapors vented free. It’s a choice born of context: concentric for the philosopher’s straight path, eccentric for the pragmatist’s angled wisdom.

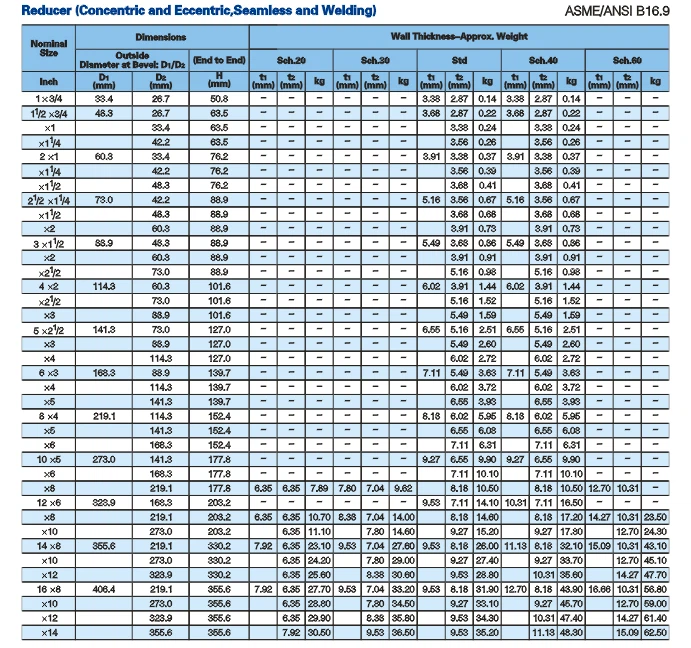

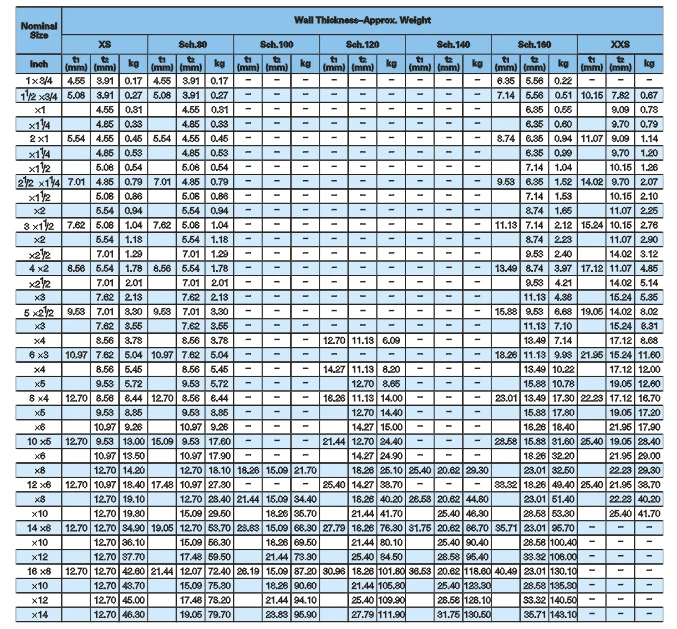

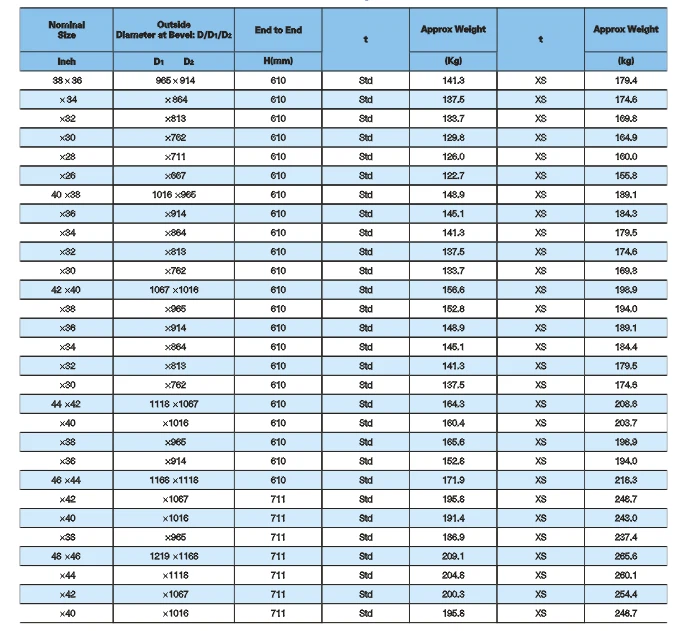

Water treatment whispers another verse: municipal mains, 48″ behemoths narrowing to service taps, where concentric efficiency minimizes head loss, calculated via Darcy-Weisbach’s equation as f(L/D)(v²/2g), friction factor f dipping low in smooth carbon bores.But to anchor this flow, let dimensions speak in their tabular tongue, not as dry edict but as a map of possibility. Consider the concentric reducer’s profile under ANSI B16.9, where sizes cascade from intimate to immense. Here’s a glimpse, drawn from the standard’s heart, for nominal pipe sizes up to 12″, schedules STD through XS, weights approximate for carbon steel density at 7.85 g/cm³:

|

Nominal Pipe Size (NPS)

|

Large End OD (mm)

|

Small End OD (mm)

|

End-to-End H (mm)

|

Approx. Weight SCH40 (kg)

|

|---|---|---|---|---|

|

3/4 x 1/2

|

26.7

|

21.3

|

38

|

0.18

|

|

1 x 3/4

|

33.4

|

26.7

|

51

|

0.27

|

|

1-1/2 x 1

|

48.3

|

33.4

|

64

|

0.59

|

|

2 x 1-1/2

|

60.3

|

48.3

|

76

|

0.95

|

|

3 x 2

|

88.9

|

60.3

|

89

|

1.9

|

|

4 x 3

|

114.3

|

88.9

|

102

|

3.2

|

|

6 x 4

|

168.3

|

114.3

|

127

|

6.8

|

|

8 x 6

|

219.1

|

168.3

|

152

|

11.3

|

|

10 x 8

|

273.1

|

219.1

|

178

|

18.1

|

|

12 x 10

|

323.9

|

273.1

|

203

|

26.7

|

These figures, precise yet forgiving—tolerances allowing +4/-0 mm on large-end bevels for NPS 10-18—reveal the reducer’s adaptability, H scaling linearly with size to ease fabrication, weights ballooning quadratically with area, a nod to logistics’ hidden tax.

For eccentrics, the table shifts subtly, H identical but the offset implicit in design, outside diameters mirroring yet the internal geometry tilting, say, with the small end’s bottom flush to the large for horizontal drainage.Delving further, the choice between concentric and eccentric unfolds like a philosopher’s debate, each excelling in physics’ subtle arenas. Concentric’s aligned axes preserve velocity profiles, reducing erosion at walls—key in abrasive slurries, where particle impact follows v² laws, concentric’s even taper halving localized wear versus abrupt contractions. Eccentric, however, triumphs in multiphase flows: imagine gas-liquid mixes in oil lines, where concentric’s symmetry traps bubbles at the crown, fostering slugs that hammer valves; the eccentric’s slant, flat side down, shears them away, maintaining stratified calm.

In vertical risers, eccentrics prevent condensate pooling in steam traps, their offset ensuring full bore drainage, while concentrics suit downcomers where symmetry aids uniform cooling. This isn’t mere preference; it’s codified in ASME’s pressure vessel code, Section VIII, where reducer selection influences stress analysis, hoop tensions σ = PD/2t modulated by the taper’s grace.Manufacturing’s nuances layer yet more depth, seamless processes evoking a sculptor’s chisel. From billet to bloom, electric arc furnaces melt scrap—80% recycled in modern mills—ladle-injected with carbon to 0.25-0.30%, alloyed with manganese for toughness. Piercing follows, the hot bloom rotated against a pointed mandrel at 200 rpm, elongating 3:1 in seconds, then rolled in pilger mills for wall precision ±0.79 mm. For reducers, the cone-forming die compresses at 900°C, metal’s recrystallization healing microvoids, yielding a fitting with elongation >22% per ASTM A234. Welded paths diverge: plate rolling on three-roll benders curves to radius, plasma-cut bevels ensuring 60° included angle, then SAW welding at 500 amps, post-weld normalized at 900°C to refine grains below 20 μm, boosting impact toughness to 27 J at -20°C for WPHY grades.

Each method carries echoes: seamless for cyclic loads, fatigue limits 10^6 cycles at 50% yield; welded for static, NDT like RT ensuring <1% reject rate.In the wilds of application, these reducers pulse with life’s industries. Oil and gas, that black-gold frontier, deploys them in gathering lines—24″ concentrics funneling from wells to 12″ trunks, carbon’s galvanic compatibility with cathodically protected steel averting corrosion cells. Refineries layer eccentrics in distillation towers, transitioning fractionation trays where vapors ascend without entrapment, flows modeled by Fanning’s friction balancing momentum. Power plants, be they coal’s fading embers or nuclear’s steady glow, thread reducers through superheater circuits: SCH120 walls containing 300 bar, concentric forms minimizing thermal gradients that warp tubes at 10^-5/°C expansion. Chemical realms add corrosives’ twist—WP5 alloy variants, 5% chrome shielding against H2S sour gas, eccentrics in agitator feeds preventing vortex air ingress. Even construction bows: HVAC ducts in skyscrapers use lighter SCH20, concentrics easing airflow per ASHRAE ducts, noise damped by symmetric transitions.

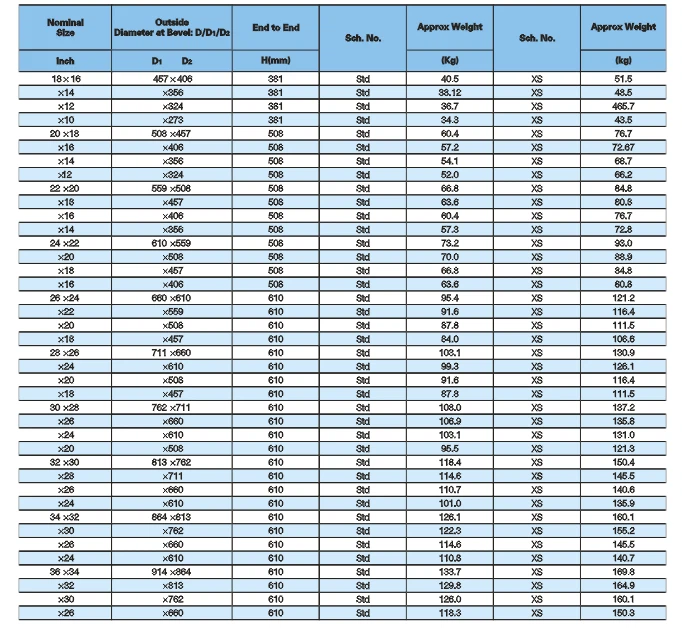

Yet, installation binds theory to turf, a ritual of alignment and arc. Bevels prepped, pipes tack-welded, GTAW roots ensure fusion without spatter, SMAW fills to 3G position for overheads. Eccentrics demand care—offset oriented per drawing, flat up for suctions—while hydrotests at 1.5x design pressure probe for leaks, soap films betraying the imperfect seal. Maintenance murmurs of vigilance: UT scans for laminations, MT for surface cracks post-thaw in Arctic ops, coatings like FBE epoxy extending life from 20 to 50 years in saline soils. Costs weave through: a 6″ SCH40 concentric at $150, welded scaling to $5000 for 48″, ROI in uptime’s currency.Envision a case: Midway through a Gulf platform retrofit, 2018’s storm surge bent risers; engineers swapped concentrics for eccentrics in mud lines, offsets quelling sand bridges, production rebounding 15% sans downtime. Or a Midwest power plant, 2022 upgrade: seamless WP91 reducers in reheater loops, 9% chrome fending 600°C oxidation, efficiency climbing 2% via smoother flows. These vignettes illuminate the multidimensional: safety’s shield against blowouts (API 5L mandates), economics’ ledger balancing capex with opex, sustainability’s arc as carbon steel recycles at 95% energy savings.Peering ahead, the stream bends toward innovation—nanocoated carbons repelling biofilms, 3D-printed prototypes testing bespoke tapers, or hybrid alloys blending WPB’s thrift with P91’s heat. Yet carbon endures, its butt weld reducers eternal in the flow’s quiet command.To extend the dimensional dialogue, let’s unfurl another table for eccentric reducers, mirroring ANSI B16.9’s wisdom, focusing on larger bores where offsets matter most, weights for SCH STD:

|

Nominal Pipe Size (NPS)

|

Large End OD (mm)

|

Small End OD (mm)

|

End-to-End H (mm)

|

Approx. Weight (kg)

|

|---|---|---|---|---|

|

14 x 12

|

355.6

|

323.9

|

229

|

38.6

|

|

16 x 14

|

406.4

|

355.6

|

254

|

50.3

|

|

18 x 16

|

457.2

|

406.4

|

279

|

65.8

|

|

20 x 18

|

508.0

|

457.2

|

305

|

82.1

|

|

24 x 20

|

609.6

|

508.0

|

356

|

118.0

|

|

30 x 24

|

762.0

|

609.6

|

406

|

195.0

|

|

36 x 30

|

914.4

|

762.0

|

457

|

290.0

|

|

42 x 36

|

1066.8

|

914.4

|

508

|

410.0

|

|

48 x 42

|

1219.2

|

1066.8

|

559

|

550.0

|

|

60 x 48

|

1524.0

|

1219.2

|

610

|

850.0

|

Here, H’s progression ensures fabricability, the eccentric’s implicit offset—half the wall difference—tailored for flow’s bias, weights reflecting volume’s swell, a practical poetry for the pipefitter’s hand.

Winding through materials’ mosaic, carbon steel’s pantheon expands: WP1 for low-alloy mildness, WP5’s chrome veil against sulfidation, up to WP91’s martensitic might for 650°C creeps. Each grades per ASTM A234, chemistry tight—carbon max 0.30% for WPB, sulfur below 0.015% to shun hot shortness—mechanicals verified by Charpy vees at -7°C. Stainless siblings like WP304 intrude for hygiene’s sake, but carbon’s throne is cost: $1-2/kg versus $4+, in realms where abrasion trumps etch.Flow assurance ties threads: CFD simulations crown concentric for compressible gases, Mach numbers <0.3 sans shock; eccentrics for inlets, NPSH margins boosted 10% by de-aeration. Regulations layer—PED in Europe demanding CE marks, API 6H for subsea welds—ensuring the reducer’s role in integrity management, RBI prioritizing high-consequence areas.In the end—or rather, the ongoing bend—these fittings remind us: engineering is flow, metal’s memory shaping fluid’s fate. From forge’s spark to pipeline’s thrum, carbon steel butt weld concentric and eccentric reducers weave the invisible web holding our world afloat.

You must be logged in to post a comment.