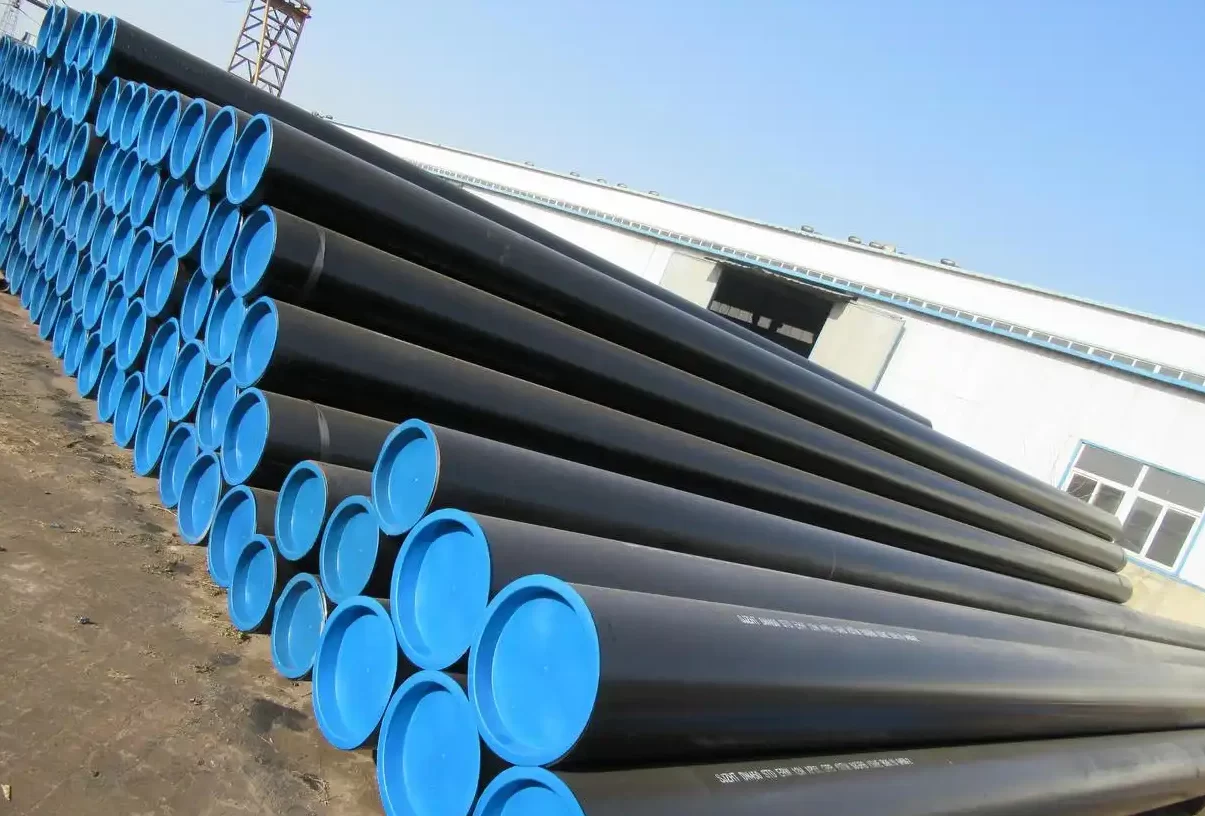

Specializing in the R&D, production and sales of EN 10216-1 P195 seamless steel pipes, we forge reliable quality with rigorous standards, providing efficiently adaptive pressure steel pipe solutions for the global industrial sector.

Our products fully comply with the EU EN 10216-1 standard, covering two quality grades: P195TR1 and P195TR2, which accurately match scenarios with different safety requirements. Thanks to the low-carbon chemical composition design (C≤0.13%), they possess excellent weldability and ductility, easily adapting to various conventional welding methods such as arc welding and gas welding, ensuring convenient and efficient installation. With stable core mechanical properties, the yield strength is ≥195MPa and the tensile strength ranges from 320-440MPa. Among them, the TR2 grade maintains excellent impact toughness even in low-temperature environments of 0℃, easily coping with working condition challenges with large temperature fluctuations.

From low-pressure boiler pipelines in thermal power stations, auxiliary transmission systems in petrochemical industry, to urban heating and water supply pipe networks, and general industrial equipment manufacturing, our P195 steel pipes have become the preferred material in various fields due to their high cost-effectiveness and stable reliability. The entire production process is equipped with an intelligent monitoring system, covering the whole process of steelmaking, piercing, rolling and heat treatment. Combined with multiple rigorous inspections such as optical emission spectrometry and ultrasonic non-destructive testing, we ensure that each batch of products has precise dimensions, smooth surfaces and qualified performance.

We provide customized specification services (outer diameter: 10.2-711mm, wall thickness: 1.6-100mm), combined with diversified surface treatment solutions such as hot-dip galvanizing and oiling, to meet the corrosion resistance requirements of different environments. Relying on a sound supply chain system, we achieve efficient delivery and full-process technical support, escorting you from product selection to after-sales follow-up. Choose us, choose the reassuring option of European standard quality, and let P195 steel pipes become a solid guarantee for the stable operation of your projects!

EN 10216-1 P195 Steel Pipe: Properties, Manufacturing, Applications and Future Trends

Abstract: EN 10216-1 P195 steel pipe is a type of non-alloy seamless steel pipe designed for pressure purposes, which has been widely used in various industrial fields due to its excellent weldability, ductility and cost-effectiveness. This paper aims to conduct a comprehensive analysis of EN 10216-1 P195 steel pipe, covering aspects such as the background and core requirements of the EN 10216-1 standard, the chemical and mechanical properties of P195 steel, the key manufacturing processes, quality control and testing methods, typical application scenarios and case studies, as well as the current market situation and future development trends. By collating and analyzing relevant standard specifications, technical data and industrial application cases, this paper reveals the technical characteristics and application value of EN 10216-1 P195 steel pipe, and provides reference for the further optimization of its production process, the expansion of application fields and the improvement of quality control level. The research shows that EN 10216-1 P195 steel pipe, with its stable performance and reasonable cost, will still occupy an important position in the medium and low pressure application fields. Meanwhile, with the promotion of intelligent manufacturing and green production concepts, its production technology will continue to upgrade, and its application prospects will be broader.

Keywords: EN 10216-1 standard; P195 steel pipe; seamless steel pipe; manufacturing process; quality control; industrial application

1. Introduction

1.1 Research Background and Significance

In the field of industrial infrastructure and equipment manufacturing, seamless steel pipes for pressure purposes play an irreplaceable role, which are widely used in energy transmission, petrochemical industry, thermal power generation, urban heating and other key fields. The performance and quality of such steel pipes directly affect the safety and reliability of the entire engineering system. With the continuous development of global industrialization and the increasing demand for energy and infrastructure construction, the requirements for the performance, quality and safety of pressure-bearing seamless steel pipes are also constantly improving.

EN 10216-1 is a European standard for seamless steel pipes for pressure purposes, which specifies the technical delivery conditions for non-alloy steel pipes with specified room temperature properties. As an important grade under this standard, P195 steel pipe is favored by the market due to its low carbon content, excellent weldability, good ductility and cost-effectiveness. The “P” in P195 represents “pressure”, and the following numerical value indicates its minimum yield strength (195 MPa). Compared with other high-strength steel grades, P195 steel pipe has obvious cost advantages in medium and low pressure applications, and its production technology is relatively mature, which has been widely used in various industrial fields. However, in the actual production and application process, there are still problems such as how to further improve the stability of product performance, optimize the production process, and expand the application scope under harsh working conditions.

Therefore, conducting in-depth research on EN 10216-1 P195 steel pipe is of great practical significance. On the one hand, it can help to deeply understand the technical characteristics and quality requirements of P195 steel pipe, provide theoretical support for the optimization of production processes and the improvement of quality control levels; on the other hand, it can clarify the application rules and potential risks of P195 steel pipe in different industrial fields, provide a basis for the rational selection and safe use of P195 steel pipe in engineering practice, and promote the healthy development of the seamless steel pipe industry.

1.2 Research Objectives and Scope

The main objectives of this paper are as follows: First, to systematically sort out the background, core content and technical requirements of the EN 10216-1 standard, and clarify the positioning and characteristics of P195 steel pipe in the standard system; second, to analyze the chemical composition and mechanical properties of EN 10216-1 P195 steel pipe, and explore the relationship between its composition and performance; third, to elaborate on the key manufacturing processes of P195 seamless steel pipe, and discuss the key control points affecting product quality; fourth, to introduce the quality control and testing methods of P195 steel pipe, and evaluate the effectiveness of various testing technologies; fifth, to summarize the typical application scenarios of P195 steel pipe, and verify its application value through practical cases; sixth, to analyze the current market situation and future development trends of P195 steel pipe, and put forward prospects for its technological upgrading and application expansion.

The research scope of this paper is mainly focused on EN 10216-1 P195 steel pipe, including its related standard specifications, material properties, manufacturing processes, quality testing, industrial applications and market trends. It does not involve other steel grades under the EN 10216 standard system (such as P235, P265, etc.) or other types of pressure-bearing steel pipes that do not comply with the EN 10216-1 standard.

1.3 Structure of the Thesis

This paper is divided into six chapters, and the specific structure is arranged as follows: Chapter 1 is the introduction, which mainly elaborates on the research background and significance of EN 10216-1 P195 steel pipe, clarifies the research objectives and scope, and introduces the overall structure of the paper. Chapter 2 focuses on the EN 10216-1 standard and the material properties of P195 steel pipe, including the origin and core requirements of the standard, as well as the chemical composition and mechanical properties of P195 steel. Chapter 3 discusses the manufacturing process of EN 10216-1 P195 seamless steel pipe, including the key processes such as steelmaking, piercing, rolling, heat treatment, and the key control points of each process. Chapter 4 introduces the quality control and testing methods of P195 steel pipe, including chemical composition testing, mechanical property testing, non-destructive testing and other aspects. Chapter 5 analyzes the typical application scenarios of EN 10216-1 P195 steel pipe, and verifies its application effect through specific engineering cases. Chapter 6 is the conclusion and prospect, which summarizes the main research results of the paper, analyzes the current challenges faced by P195 steel pipe, and looks forward to its future development trends. Finally, the references are listed.

2. EN 10216-1 Standard and Material Properties of P195 Steel Pipe

2.1 Overview of EN 10216-1 Standard

EN 10216-1 is a part of the European EN 10216 standard series, whose full name is “Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 1: Non-alloy steel tubes with specified room temperature properties”. This standard replaces the old DIN 17175 and DIN 1629 standards, and is specially formulated for seamless steel tubes used in pressure-bearing applications at room temperature. It interacts with other European pressure equipment standards (such as PED 2014/68/EU) to form a complete technical specification system for pressure-bearing steel pipes, ensuring the safety and reliability of pressure-bearing steel pipes in industrial applications.

The EN 10216-1 standard specifies the technical delivery conditions for two quality grades of P195 steel pipe: TR1 (basic requirements) and TR2 (more stringent requirements). The main difference between the two grades lies in the impact performance requirements and inspection criteria. TR2 grade requires specified impact energy values at 0℃ and -10℃, while TR1 grade does not have mandatory impact performance requirements. In addition, the TR2 grade also has more rigorous inspection requirements in terms of surface quality, dimensional tolerance and non-destructive testing, making it more suitable for applications with higher safety requirements, such as pressure equipment in harsh working environments.

The scope of application of the EN 10216-1 standard covers seamless steel pipes with circular cross-sections made of non-alloy steel, which are mainly used for pressure purposes at room temperature. The standard specifies the dimensional parameters of the steel pipes, including the outer diameter range of 10.2 mm – 711 mm (1/8″ – 28″, DN6 – DN700), the wall thickness range of 1.6 mm – 100 mm, and the unit length range of 1.5 m – 15 m. At the same time, the standard also stipulates the surface coating, end type and connection methods of the steel pipes. The surface coating can be varnished, black, oiled or hot-dip galvanized; the end type includes square cut, bevelled, threaded and grooved; the connection methods include fitting, flange, coupling, clamp, pipe shoulder and welding, which provides a variety of options for different application scenarios.

2.2 Chemical Composition of EN 10216-1 P195 Steel Pipe

The chemical composition of EN 10216-1 P195 steel pipe is strictly regulated by the standard, which directly determines its mechanical properties and process performance. According to the cast analysis requirements of the EN 10216-1 standard, the chemical composition limits of P195 steel (including TR1 and TR2 grades) are shown in Table 1.

|

Element

|

Content Limit (max, % by mass)

|

|---|---|

|

Carbon (C)

|

0.13

|

|

Silicon (Si)

|

0.35

|

|

Manganese (Mn)

|

0.70

|

|

Phosphorus (P)

|

0.025

|

|

Sulfur (S)

|

0.020

|

|

Chromium (Cr)

|

0.30

|

|

Molybdenum (Mo)

|

0.08

|

|

Nickel (Ni)

|

0.30

|

|

Copper (Cu)

|

0.30

|

|

Niobium (Nb)

|

0.010

|

|

Titanium (Ti)

|

0.04

|

|

Vanadium (V)

|

0.02

|

|

Cr + Cu + Mo + Ni

|

0.70

|

It should be noted that for the P195TR2 grade, the standard also requires a minimum aluminum (Al) content of 0.02% (mass fraction), while the P195TR1 grade has no mandatory requirement for aluminum content. Aluminum acts as a deoxidizer in steel, which can effectively reduce the oxygen content in the steel, improve the purity of the steel, and thus enhance the ductility and toughness of the steel pipe.

The chemical composition of P195 steel pipe has the following characteristics: First, the carbon content is low (≤0.13%), which ensures good weldability and ductility of the steel pipe, making it suitable for applications that require a lot of welding operations. Second, the content of harmful elements such as phosphorus and sulfur is strictly limited (P≤0.025%, S≤0.020%), which can prevent the steel from becoming brittle and ensure good toughness and ductility of the steel pipe. Third, the content of alloying elements such as silicon and manganese is controlled within a reasonable range. Silicon acts as a deoxidizer and can improve the strength and hardness of the steel; manganese can enhance the strength and hardness of the steel while reducing the adverse effects of sulfur. The reasonable matching of these elements makes P195 steel pipe have a good balance between strength and ductility.

2.3 Mechanical Properties of EN 10216-1 P195 Steel Pipe

The mechanical properties of EN 10216-1 P195 steel pipe are important indicators to measure its performance and applicability, which are strictly regulated by the standard. The mechanical properties mainly include tensile properties (yield strength, tensile strength, elongation) and impact properties (absorbed energy). The specific requirements of the EN 10216-1 standard for the mechanical properties of P195 steel pipe are shown in Table 2.

|

Steel Grade

|

Wall Thickness (t, mm)

|

Upper Yield Strength (ReH, min, MPa)

|

Tensile Strength (Rm, MPa)

|

Elongation (A, min, %)

|

Minimum Average Absorbed Energy (Kv, J) at 0℃

|

|---|---|---|---|---|---|

|

P195TR1

|

t ≤ 16

|

195

|

320 – 440

|

27

|

–

|

|

16 < t ≤ 40

|

185

|

–

|

|||

|

40 < t ≤ 60

|

175

|

–

|

|||

|

P195TR2

|

t ≤ 16

|

195

|

320 – 440

|

27

|

40

|

|

16 < t ≤ 40

|

185

|

28

|

|||

|

40 < t ≤ 60

|

175

|

27

|

From Table 2, it can be seen that the yield strength of P195 steel pipe decreases with the increase of wall thickness. This is because with the increase of wall thickness, the cooling rate of the steel pipe during heat treatment decreases, resulting in a coarser grain structure and a slight decrease in strength. The tensile strength of P195 steel pipe is in the range of 320 – 440 MPa, which can meet the requirements of medium and low pressure bearing applications. The elongation of P195 steel pipe is not less than 27%, indicating that it has good ductility and can absorb a lot of energy before failure, which is beneficial to improving the safety of the steel pipe in the process of use.

The impact performance is an important difference between P195TR1 and P195TR2 grades. The P195TR2 grade requires a minimum average absorbed energy of 40 J at 0℃ when the wall thickness is ≤16 mm, and the absorbed energy decreases slightly with the increase of wall thickness. The P195TR1 grade has no mandatory requirements for impact performance, so it is mainly used in general applications where impact resistance is not critical, while the P195TR2 grade is more suitable for applications that may be subjected to impact loads, such as pressure pipelines in areas with large temperature changes.

In addition, P195 steel pipe also has good process performance, such as excellent cold bending performance and welding performance. Its cold bending test can be carried out according to the relevant requirements of the standard without cracks; its welding can be completed by common welding methods (such as arc welding, gas welding, etc.), and the weld joint has good strength and toughness after welding, which can meet the requirements of engineering applications.

3. Manufacturing Process of EN 10216-1 P195 Seamless Steel Pipe

The manufacturing process of EN 10216-1 P195 seamless steel pipe is complex, involving multiple processes such as steelmaking, billet heating, piercing, rolling, heat treatment, and finishing. Each process has strict technical requirements and quality control points, which directly affect the final performance and quality of the steel pipe. The following will elaborate on the key manufacturing processes of P195 seamless steel pipe and their key control points.

3.1 Steelmaking Process

The steelmaking process is the first link in the manufacturing of P195 seamless steel pipe, and the quality of the molten steel directly determines the internal quality of the steel pipe. At present, the steelmaking process of P195 steel mainly adopts the electric arc furnace (EAF) + LF (ladle furnace) refining process. This process has the advantages of high smelting efficiency, good quality of molten steel and strong adaptability to raw materials.

The key control points of the steelmaking process are as follows: First, the control of raw materials. The scrap steel and other raw materials used for smelting must meet the relevant quality requirements, and the content of harmful elements (such as phosphorus, sulfur, etc.) must be strictly controlled to avoid affecting the quality of the molten steel. Second, the control of smelting temperature. The smelting temperature of the electric arc furnace is generally controlled at 1580℃ – 1620℃, which ensures the complete melting of the raw materials and the sufficient reaction of the elements. Third, the deoxidation and desulfurization treatment. During the smelting process, deoxidizers such as silicon manganese alloy and aluminum are added to remove the oxygen in the molten steel; at the same time, desulfurization agents are added to reduce the sulfur content in the molten steel to meet the standard requirements (S≤0.020%). Fourth, the LF refining process. After the molten steel is smelted in the electric arc furnace, it is transferred to the LF furnace for refining. The LF refining can further adjust the composition of the molten steel, improve the purity of the molten steel, and make the composition of the molten steel more uniform. During the refining process, the temperature and time of the molten steel are strictly controlled to ensure the effect of refining.

In addition, some advanced steelmaking enterprises also adopt calcium treatment technology in the steelmaking process. By adding calcium alloy to the molten steel, the shape of inclusions in the steel can be improved, making the inclusions spherical, which can effectively improve the toughness and fatigue performance of the steel pipe.

3.2 Billet Heating Process

After the steelmaking process, the molten steel is cast into billets (usually round billets) through continuous casting. The billets need to be heated before piercing to improve their plasticity and reduce the resistance during piercing. The heating quality of the billets directly affects the surface quality and internal structure of the steel pipe.

The key control points of the billet heating process are as follows: First, the heating temperature. The heating temperature of P195 steel billets is generally controlled at 1200℃ – 1250℃. If the heating temperature is too low, the plasticity of the billets is poor, which may lead to cracks during piercing; if the heating temperature is too high, the billets may be overheated or burned, resulting in coarse grains and reduced performance of the steel pipe. Second, the heating time. The heating time of the billets should be sufficient to ensure that the temperature inside and outside the billets is uniform. The heating time is generally determined according to the diameter of the billets and the heating temperature, and it is usually 2 – 4 hours. Third, the atmosphere in the furnace. The atmosphere in the heating furnace should be controlled to avoid oxidation and decarburization of the billets. Generally, a reducing atmosphere or a neutral atmosphere is adopted to reduce the oxidation of the billets’ surface.

3.3 Piercing and Rolling Process

Piercing and rolling are the core processes of manufacturing seamless steel pipes, which transform the round billets into hollow pipe blanks and then into finished steel pipes with specified dimensions. The piercing process is to pierce the heated round billets into hollow pipe blanks through a piercing mill; the rolling process is to further process the pipe blanks into steel pipes with specified outer diameter and wall thickness through a rolling mill (such as a mandrel mill, a plug mill, etc.).

The key control points of the piercing process are as follows: First, the selection of piercing parameters. The piercing parameters include the rotation speed of the piercing roll, the feed rate, the angle of the piercing roll, etc. These parameters need to be reasonably matched according to the diameter and wall thickness of the billets and the pipe blanks. If the parameters are not properly matched, it may lead to defects such as uneven wall thickness, eccentricity and surface cracks of the pipe blanks. Second, the cooling of the piercing tool. The piercing roll and the mandrel are important tools in the piercing process, which will generate a lot of heat during the piercing process. Therefore, effective cooling measures must be taken to avoid overheating and wear of the tools, which will affect the quality of the pipe blanks.

The key control points of the rolling process are as follows: First, the control of rolling temperature. The rolling temperature is generally controlled at 950℃ – 1050℃. If the rolling temperature is too low, the rolling resistance increases, which may lead to cracks in the steel pipe; if the rolling temperature is too high, the grain size of the steel pipe increases, which reduces the strength and toughness of the steel pipe. Second, the adjustment of rolling mill parameters. The rolling mill parameters include the rotation speed of the roll, the feed rate, the reduction amount, etc. These parameters need to be adjusted according to the dimensions of the pipe blanks and the requirements of the finished steel pipes to ensure that the outer diameter and wall thickness of the finished steel pipes meet the standard requirements. The wall thickness tolerance of P195 seamless steel pipe is generally required to be ±7.5%. Third, the straightening of the steel pipe. After rolling, the steel pipe may have bending defects, so it needs to be straightened. The straightening process should be carried out at an appropriate temperature to avoid residual stress in the steel pipe.

3.4 Heat Treatment Process

The heat treatment process is an important process to improve the mechanical properties of P195 seamless steel pipe. Through heat treatment, the internal structure of the steel pipe can be adjusted, the grain size can be refined, and the strength, toughness and ductility of the steel pipe can be improved. The heat treatment process of P195 steel pipe mainly adopts normalizing treatment, and some special requirements may also adopt normalizing + tempering treatment.

The key control points of the normalizing treatment process are as follows: First, the heating temperature. The normalizing temperature of P195 steel pipe is generally controlled at 900℃ – 960℃. At this temperature, the steel pipe is fully austenitized, which is conducive to the formation of uniform ferrite and pearlite structure after cooling. Second, the holding time. The holding time should be sufficient to ensure that the entire cross-section of the steel pipe is fully austenitized. The holding time is generally determined according to the wall thickness of the steel pipe, and it is usually 1 – 2 hours. Third, the cooling method. The normalizing cooling is generally air cooling, which can ensure that the steel pipe cools at an appropriate speed, forming a fine and uniform ferrite + pearlite structure. If the cooling speed is too fast, it may form martensite structure, which will increase the hardness of the steel pipe and reduce the ductility; if the cooling speed is too slow, the grain size will be coarse, which will reduce the strength of the steel pipe.

For P195TR2 grade steel pipe, due to its higher requirements for impact performance, tempering treatment may be added on the basis of normalizing. The tempering temperature is generally controlled at 680℃ – 720℃. Through tempering treatment, the residual stress in the steel pipe can be eliminated, the toughness of the steel pipe can be further improved, and the impact performance of the steel pipe can meet the standard requirements.

3.5 Finishing Process

The finishing process is the last link in the manufacturing of P195 seamless steel pipe, which includes processes such as cutting, surface treatment, and inspection. The purpose of the finishing process is to make the steel pipe meet the specified dimensional accuracy, surface quality and delivery requirements.

The key control points of the finishing process are as follows: First, the cutting of the steel pipe. The steel pipe is cut into the specified length (1.5 m – 15 m) by cutting tools (such as sawing machines, flame cutting machines, etc.). The cutting surface should be flat and free of burrs to avoid affecting the connection and use of the steel pipe. Second, the surface treatment of the steel pipe. The surface of the steel pipe should be cleaned to remove oxide scale, oil stains and other impurities. According to the requirements of customers and standards, the surface of the steel pipe can be subjected to varnishing, blackening, oiling or hot-dip galvanizing treatment. The hot-dip galvanizing treatment can improve the corrosion resistance of the steel pipe and extend its service life. Third, the inspection of the steel pipe. The finished steel pipe needs to undergo strict dimensional inspection, surface quality inspection and performance testing to ensure that it meets the requirements of the EN 10216-1 standard. The unqualified steel pipes are sorted out and handled accordingly.

4. Quality Control and Testing Methods of EN 10216-1 P195 Steel Pipe

The quality control and testing of EN 10216-1 P195 steel pipe run through the entire manufacturing process, from the incoming inspection of raw materials to the final inspection of finished products. Strict quality control and scientific testing methods are important guarantees for ensuring the performance and quality of P195 steel pipe. The following will introduce the quality control system and common testing methods of P195 steel pipe.

4.1 Quality Control System

The quality control system of EN 10216-1 P195 steel pipe adopts a full-process control mode, which includes raw material quality control, process quality control and finished product quality control.

Raw material quality control mainly involves the inspection of scrap steel, alloy materials and other raw materials. The chemical composition, mechanical properties and surface quality of the raw materials must meet the relevant requirements. For scrap steel, it is necessary to check for harmful elements and impurities; for alloy materials, it is necessary to check the composition and content to ensure that the smelted molten steel meets the standard requirements.

Process quality control is the core of the quality control system, which involves the quality control of each manufacturing process such as steelmaking, billet heating, piercing, rolling, heat treatment and finishing. In the steelmaking process, the composition and temperature of the molten steel are continuously monitored; in the billet heating process, the heating temperature and time are controlled; in the piercing and rolling processes, the process parameters are adjusted in real time to ensure the dimensional accuracy and internal quality of the steel pipe; in the heat treatment process, the heating temperature, holding time and cooling speed are strictly controlled to ensure the mechanical properties of the steel pipe; in the finishing process, the dimensional inspection and surface treatment of the steel pipe are carried out to ensure the delivery quality of the steel pipe.

Finished product quality control mainly involves the final inspection of the finished steel pipe, including dimensional inspection, surface quality inspection, chemical composition testing, mechanical property testing and non-destructive testing. Only the steel pipes that pass all the inspections can be delivered. For the unqualified steel pipes, they are marked and handled according to the relevant regulations, and cannot be delivered and used.

With the development of intelligent manufacturing technology, many steel pipe manufacturers have introduced intelligent monitoring systems (such as MES systems) in the production process to realize real-time monitoring and data collection of process parameters, which can timely find and solve quality problems in the production process, and improve the qualification rate of products. For example, Tianjin Pipe Group has realized full-process intelligent production through the MES system, and the product qualification rate has been increased to 99.3%.

4.2 Common Testing Methods

4.2.1 Chemical Composition Testing

Chemical composition testing is an important method to ensure that the chemical composition of P195 steel pipe meets the standard requirements. Common chemical composition testing methods include optical emission spectrometry (OES) and X-ray fluorescence spectrometry (XRF).

Optical emission spectrometry is a commonly used testing method in the steel industry, which has the advantages of fast testing speed, high accuracy and wide detection range. It can simultaneously detect multiple elements in the steel pipe, including carbon, silicon, manganese, phosphorus, sulfur and other elements. The testing process is to excite the sample to be tested into a plasma state through an electric arc or a spark, and then analyze the emission spectrum of the plasma to determine the type and content of the elements.

X-ray fluorescence spectrometry is a non-destructive testing method, which is mainly used for the rapid analysis of the chemical composition of the surface of the steel pipe. It has the advantages of non-destructive testing, fast testing speed and simple operation. However, its detection accuracy is slightly lower than that of optical emission spectrometry, and it is mainly used for preliminary screening and on-site rapid testing.

4.2.2 Mechanical Property Testing

Mechanical property testing is used to verify whether the mechanical properties of P195 steel pipe (such as yield strength, tensile strength, elongation, impact energy) meet the standard requirements. Common mechanical property testing methods include tensile test, impact test and hardness test.

Tensile test is carried out on a tensile testing machine. The test sample is a standard tensile sample cut from the steel pipe. During the test, the tensile testing machine applies a tensile force to the sample until the sample breaks. The tensile testing machine automatically records the tensile force and the elongation of the sample, and calculates the yield strength, tensile strength and elongation of the steel pipe. The tensile test can intuitively reflect the tensile performance of the steel pipe and is an important basis for evaluating the strength and ductility of the steel pipe.

Impact test is mainly used to test the impact toughness of P195 steel pipe, especially for the P195TR2 grade which has mandatory impact performance requirements. Common impact test methods include Charpy V-notch impact test. The test sample is a standard V-notch sample cut from the steel pipe. During the test, the pendulum of the impact testing machine hits the sample at a certain height, and the absorbed energy of the sample when it breaks is measured. The impact test is carried out at different temperatures (such as 0℃, -10℃) according to the standard requirements to evaluate the impact resistance of the steel pipe under different temperature conditions.

Hardness test is a rapid testing method to evaluate the hardness of P195 steel pipe. Common hardness testing methods include Brinell hardness test and Rockwell hardness test. The hardness test is to press a hard indenter into the surface of the steel pipe under a certain load, and evaluate the hardness of the steel pipe by measuring the diameter or depth of the indentation. The hardness of the steel pipe is related to its strength and toughness. Through the hardness test, the mechanical properties of the steel pipe can be preliminarily judged.

4.2.3 Non-Destructive Testing

Non-destructive testing is a testing method that does not damage the performance and structure of the steel pipe, which is mainly used to detect internal and surface defects of P195 steel pipe. Common non-destructive testing methods for P195 steel pipe include ultrasonic testing (UT), eddy current testing (ET) and magnetic particle testing (MT).

Ultrasonic testing is a commonly used non-destructive testing method for detecting internal defects of steel pipes (such as cracks, inclusions, voids, etc.). It uses the propagation characteristics of ultrasonic waves in the steel pipe. When the ultrasonic waves encounter defects, they will be reflected, refracted and scattered. The ultrasonic testing instrument receives and analyzes these signals to determine the position, size and shape of the defects. Ultrasonic testing has the advantages of high detection accuracy, deep detection depth and wide application range, and is widely used in the non-destructive testing of seamless steel pipes. The ultrasonic testing of P195 steel pipe generally complies with the requirements of the EN 10246-3 standard.

Eddy current testing is mainly used to detect surface and near-surface defects of steel pipes (such as surface cracks, pits, etc.). It uses the principle of electromagnetic induction. When an alternating current is passed through the coil, an alternating magnetic field is generated. When the coil is close to the steel pipe, an eddy current is induced in the steel pipe. If there are defects on the surface or near-surface of the steel pipe, the distribution of the eddy current will change, which will cause changes in the impedance of the coil. The eddy current testing instrument detects these changes to determine the presence and location of defects. Eddy current testing has the advantages of fast testing speed, non-contact testing and high sensitivity to surface defects, and is suitable for the rapid inspection of the surface quality of steel pipes.

Magnetic particle testing is also used to detect surface and near-surface defects of steel pipes. It uses the principle that the magnetic flux leakage is generated at the defect when the steel pipe is magnetized. The magnetic particles (dry powder or wet suspension) are sprinkled on the surface of the magnetized steel pipe. The magnetic particles will be adsorbed at the defect due to the magnetic flux leakage, forming a magnetic particle accumulation, which can visually show the position and shape of the defect. Magnetic particle testing has the advantages of simple operation, high sensitivity and intuitive display of defects, but it can only be used for magnetic materials (such as P195 steel pipe) and is not suitable for non-magnetic materials.

5. Application Scenarios and Case Studies of EN 10216-1 P195 Steel Pipe

EN 10216-1 P195 steel pipe has the characteristics of good weldability, ductility, cost-effectiveness and stable performance, and is widely used in various industrial fields. The following will introduce the typical application scenarios of P195 steel pipe and verify its application effect through practical engineering cases.

5.1 Typical Application Scenarios

5.1.1 Thermal Power Generation Industry

In the thermal power generation industry, P195 steel pipe is mainly used in low-pressure boiler water pipes, flue pipes, air preheater pipes and other components. These components work in medium and low pressure environments, and have requirements for the weldability and ductility of the steel pipe. P195 steel pipe can meet these requirements, and its cost is relatively low, which can reduce the investment cost of power plants. For example, in small and medium-sized thermal power plants, P195 steel pipe is widely used as the water supply pipe and flue gas discharge pipe of low-pressure boilers.

5.1.2 Petrochemical Industry

In the petrochemical industry, P195 steel pipe is used in the transportation of low-pressure oil and gas, as well as in the auxiliary pipelines of petrochemical equipment (such as catalytic cracking units, distillation units, etc.). These pipelines are not in direct contact with high-temperature and high-pressure corrosive media, and the requirements for the strength and corrosion resistance of the steel pipe are relatively low. P195 steel pipe can meet the requirements of these applications, and its excellent weldability is conducive to the installation and maintenance of the pipelines.

5.1.3 Urban Heating and Water Supply Industry

In the urban heating and water supply industry, P195 steel pipe is widely used as the main pipeline of urban heating networks and water supply networks. Urban heating and water supply pipelines work in low-pressure environments, and have requirements for the ductility and corrosion resistance of the steel pipe. P195 steel pipe after hot-dip galvanizing treatment has good corrosion resistance, which can adapt to the urban underground environment and extend the service life of the pipelines. At the same time, its good ductility can withstand the deformation caused by ground settlement and temperature changes, ensuring the safety and reliability of the heating and water supply systems.

5.1.4 General Industrial Equipment Manufacturing

In the field of general industrial equipment manufacturing, P195 steel pipe is used in the manufacture of various pressure vessels, hydraulic cylinders, pneumatic cylinders and other components. These components have requirements for the strength and ductility of the steel pipe, and P195 steel pipe can meet these requirements. Its mature production technology and reasonable cost make it a preferred material for many equipment manufacturers.

5.2 Case Studies

5.2.1 Case 1: Application of P195 Steel Pipe in a Small Thermal Power Plant Boiler Pipeline

Project Background: A small thermal power plant in northern China was built in 2020, with an installed capacity of 50 MW. The low-pressure boiler of the power plant needs to be equipped with a large number of water pipes and flue pipes. After comprehensive consideration of performance requirements, cost and other factors, the power plant chose EN 10216-1 P195TR1 steel pipe as the material for these pipelines. The specifications of the steel pipe are φ57×3.5 mm, and the total usage is 800 meters.

Application Process and Effect Evaluation: During the construction process, the P195TR1 steel pipe was welded by arc welding. Due to the good weldability of the steel pipe, the welding process was smooth, and the weld joint had no defects such as cracks and porosity after inspection. After the power plant was put into operation, the boiler pipelines made of P195TR1 steel pipe operated stably. The operating pressure of the pipelines is 1.2 MPa, and the operating temperature is 180℃, which is within the applicable range of P195 steel pipe. After one year of operation, the pipelines were inspected by ultrasonic testing, and no internal defects and obvious corrosion were found. The wall thickness of the pipelines remained basically unchanged, and the operation status was good. The use of P195TR1 steel pipe not only met the performance requirements of the boiler pipelines, but also reduced the pipeline purchase cost by about 15% compared with the use of P235 steel pipe, achieving good economic benefits.

5.2.2 Case 2: Application of P195 Steel Pipe in Urban Heating Network Reconstruction Project

Project Background: An urban heating network reconstruction project in eastern China involves the reconstruction of 2 kilometers of old heating pipelines. The original pipelines were made of ordinary carbon steel pipes, which had serious corrosion after long-term use, resulting in heat loss and potential safety hazards. The reconstruction project requires that the new pipelines have good corrosion resistance, ductility and cost-effectiveness. After investigation and comparison, the project chose EN 10216-1 P195TR2 steel pipe with hot-dip galvanizing treatment. The specifications of the steel pipe are φ159×6 mm, and the total usage is 2000 meters.

Application Process and Effect Evaluation: Before the installation of the steel pipe, the surface quality and dimensional accuracy of the steel pipe were inspected, and all indicators met the requirements of the EN 10216-1 standard. During the installation process, the steel pipe was connected by flange connection, which was convenient and fast. After the completion of the reconstruction project, the heating network was put into operation in the heating season of 2022-2023. The operating pressure of the heating network is 0.8 MPa, and the operating temperature is 120℃. After two heating seasons of operation, the pipelines were inspected. The surface of the hot-dip galvanized P195TR2 steel pipe had no obvious corrosion and rust, and the thermal insulation effect of the heating network was significantly improved. The heat loss was reduced by about 20% compared with the original pipelines. At the same time, the good ductility of the P195TR2 steel pipe ensured that the pipelines could withstand the deformation caused by ground settlement and temperature changes, and no pipeline leakage and other safety accidents occurred during the operation period. The application of P195TR2 steel pipe in this urban heating network reconstruction project achieved good social and economic benefits.

5.2.3 Case 3: Application of P195 Steel Pipe in Petrochemical Auxiliary Pipeline

Project Background: A petrochemical plant in southern China carried out an expansion project of the catalytic cracking unit. The auxiliary pipeline of the unit (used for transporting low-pressure compressed air) needs to be newly laid. The design pressure of the pipeline is 0.6 MPa, and the design temperature is 80℃. Considering the working conditions and cost factors, the plant chose EN 10216-1 P195TR1 steel pipe. The specifications of the steel pipe are φ89×4 mm, and the total usage is 500 meters.

Application Process and Effect Evaluation: The P195TR1 steel pipe used in the project was produced by an intelligent production line, and the quality was stable. During the installation process, the steel pipe was welded by gas welding, and the weld joint was inspected by eddy current testing, which met the quality requirements. After the completion of the expansion project, the auxiliary pipeline operated stably. The compressed air transported by the pipeline had no impurities, and the pipeline had no air leakage. After half a year of operation, the pipeline was inspected, and no corrosion and defects were found. The use of P195TR1 steel pipe not only met the requirements of the auxiliary pipeline, but also reduced the project cost, which was praised by the project party.

6. Market Situation and Future Development Trends of EN 10216-1 P195 Steel Pipe

6.1 Current Market Situation

At present, the global market demand for EN 10216-1 P195 steel pipe is relatively stable, mainly concentrated in the fields of thermal power generation, urban heating and water supply, petrochemical industry and general industrial equipment manufacturing. According to the 2024 industry report data, the global market scale of seamless steel pipes for pressure purposes (including P195, P235, P265 and other grades) is about 280 million tons, of which P195 steel pipe accounts for about 20% – 25%. China is the world’s largest producer and consumer of P195 steel pipe, accounting for about 45% of the global market share. The main domestic production enterprises include Tianjin Pipe Group, Baoshan Iron & Steel Co., Ltd., Hengyang Valin Steel Tube Group Co., Ltd., etc.; the main international production enterprises include Vallourec, Tenaris and other well-known steel pipe manufacturers.

In terms of market price, the price of P195 steel pipe fluctuates with the changes of raw material prices (such as iron ore, scrap steel) and market supply and demand. According to the market data in the second quarter of 2025, the domestic market price of P195 steel pipe is 5800 – 6200 yuan/ton (tax included), which is 8% lower than the same period last year, mainly affected by the decline in iron ore prices. In the international market, the price of P195 steel pipe is affected by factors such as exchange rates, trade policies and transportation costs, and the price in different regions varies slightly.

In terms of export, with the acceleration of infrastructure construction in countries along the “Belt and Road”, the export volume of China’s P195 steel pipe has increased significantly. According to the 2025 customs data, the export volume of China’s P195 steel pipe increased by 23% year-on-year, and the main export destinations include Southeast Asia, South Asia, Africa and other regions. The main reasons for the increase in exports are the stable quality of China’s P195 steel pipe, reasonable price and perfect after-sales service.

6.2 Challenges Faced by P195 Steel Pipe

Although EN 10216-1 P195 steel pipe has broad application prospects, it also faces some challenges in the current market environment.

First, the challenge of alternative materials. With the development of material science and technology, some new materials (such as high-strength alloy steel, composite materials) are constantly emerging. These materials have higher strength, corrosion resistance and high-temperature resistance, and are gradually replacing P195 steel pipe in some high-end applications. For example, in some ultra-supercritical thermal power units, T91/P92 high-alloy steel pipes are used instead of P195 steel pipes due to their better high-temperature and high-pressure resistance. In addition, in some low-pressure applications, plastic pipes (such as PE pipes, PVC pipes) are also replacing P195 steel pipes due to their lower cost and easier installation.

Second, the challenge of environmental protection policies. With the increasing emphasis on environmental protection in various countries, the environmental protection requirements for the steel industry are becoming more and more stringent. The production process of P195 steel pipe involves steelmaking, heating and other links, which will produce a large amount of carbon dioxide, sulfur dioxide and other pollutants. Steel pipe manufacturers need to increase investment in environmental protection to meet the requirements of environmental protection policies, which will increase the production cost of P195 steel pipe.

Third, the challenge of market competition. The market competition of P195 steel pipe is fierce. There are a large number of production enterprises at home and abroad, and the product homogeneity is serious. In order to occupy the market, some enterprises adopt the method of reducing prices, which leads to the decline of the overall profit level of the industry. At the same time, the requirements of customers for the quality and performance of P195 steel pipe are constantly improving, which puts forward higher requirements for the production technology and quality control level of enterprises.

6.3 Future Development Trends

In view of the current market situation and challenges, the future development of EN 10216-1 P195 steel pipe will focus on technological upgrading, green transformation and application expansion, aiming to enhance core competitiveness and adapt to the changing market and policy environment. The specific development trends are as follows:

First, the intelligent upgrading of the production process. With the in-depth advancement of Industry 4.0, intelligent manufacturing will become the core direction of the transformation and upgrading of the P195 steel pipe production industry. On the one hand, enterprises will further popularize the application of intelligent monitoring and control systems (such as MES, ERP) in the production process, realizing real-time collection, analysis and feedback of full-process parameters (such as smelting temperature, rolling speed, heat treatment time). This will help to accurately control product quality, reduce the occurrence of unqualified products, and improve production efficiency. For example, the application of digital twin technology can simulate the entire production process of P195 steel pipe, predict potential quality risks in advance, and optimize process parameters. On the other hand, the integration of automated production equipment will be strengthened. The use of robot arms, automatic piercing machines, and automatic inspection lines will replace manual operations in key links such as blanking, piercing, and testing, reducing human errors and improving production stability. At present, some leading enterprises have taken the lead in realizing the automation of the rolling process of P195 steel pipe, and the production efficiency has been increased by more than 30% compared with the traditional manual operation mode.

Second, the green transformation of production. Under the background of global carbon neutrality, green and low-carbon production will become an important threshold for the survival and development of P195 steel pipe manufacturers. Enterprises will increase investment in energy conservation and emission reduction technologies, and promote the transformation of the production process to low-carbonization. In the steelmaking link, the proportion of scrap steel in raw materials will be further increased, and the electric arc furnace smelting process with lower carbon emissions will be optimized to reduce carbon dioxide emissions. At the same time, new energy-saving technologies such as waste heat recovery and utilization will be widely applied. For example, the waste heat generated in the billet heating and heat treatment processes can be recycled to generate electricity or supply heat, improving energy utilization efficiency. In addition, enterprises will strengthen the treatment of pollutants such as flue gas and wastewater. The installation of high-efficiency desulfurization, denitrification and dust removal equipment will ensure that flue gas emissions meet national and international environmental protection standards; the recycling and reuse of wastewater will reduce water resource consumption. It is expected that by 2030, the carbon emission per ton of P195 steel pipe in major production enterprises will be reduced by 25% compared with the current level, and the comprehensive energy consumption will be reduced by more than 20%.

Third, the functional modification and performance enhancement of products. Faced with the impact of alternative materials, improving the added value of P195 steel pipe through functional modification will become an important way to expand its application fields. On the one hand, the corrosion resistance of P195 steel pipe will be further enhanced. In addition to the existing hot-dip galvanizing treatment, new surface treatment technologies such as ceramic coating, epoxy resin coating and laser cladding will be widely used. These technologies can form a more dense and wear-resistant protective layer on the surface of the steel pipe, making it suitable for more harsh corrosion environments (such as coastal areas with high salt spray, industrial areas with heavy pollution). For example, the P195 steel pipe treated with epoxy resin coating has good corrosion resistance in acidic and alkaline environments, and its service life can be extended by 2-3 times compared with ordinary galvanized steel pipes. On the other hand, the strength and toughness of P195 steel pipe will be properly improved through microalloying technology. On the premise of ensuring low carbon content and good weldability, a small amount of microalloying elements such as vanadium and titanium will be added to refine the grain structure of the steel, thereby improving the yield strength and impact toughness of the steel pipe. This will enable P195 steel pipe to meet the requirements of some medium-pressure application scenarios that were previously dominated by high-strength steel grades, expanding its application scope.

Fourth, the expansion of application fields. While consolidating the traditional application fields (such as thermal power generation, urban heating and water supply), P195 steel pipe will actively explore new application scenarios. In the field of renewable energy, with the rapid development of solar thermal power generation and biomass power generation, P195 steel pipe can be used in the low-pressure pipeline systems of related equipment, such as heat collection pipelines and auxiliary water supply pipelines. In the field of agricultural irrigation, the P195 steel pipe with good corrosion resistance and cost-effectiveness can replace traditional plastic pipes and cement pipes, especially in large-scale agricultural irrigation projects in arid and semi-arid areas, where it has obvious advantages in service life and pressure-bearing capacity. In addition, with the acceleration of urbanization in emerging markets (such as Southeast Asia and Africa), the demand for P195 steel pipe in urban infrastructure construction (such as water supply and drainage, gas transmission) will continue to grow. Enterprises will adjust product specifications and performance according to the specific needs of different regions and fields, and develop customized P195 steel pipe products to meet diversified market demands.

Fifth, the optimization of the global supply chain layout. As the largest producer and consumer of P195 steel pipe, China will further strengthen international cooperation and optimize the global supply chain layout. On the one hand, enterprises will set up production bases or processing centers in key export regions (such as Southeast Asia, Africa) to reduce transportation costs and avoid trade barriers. For example, some domestic enterprises have plans to build P195 steel pipe processing plants in Indonesia and Vietnam, which will not only meet the local market demand but also radiate to surrounding countries. On the other hand, enterprises will strengthen technological exchanges and cooperation with international advanced steel pipe manufacturers, introduce advanced production technologies and quality control experience, and improve the international competitiveness of products. At the same time, the standardization level of P195 steel pipe will be further improved. While complying with the EN 10216-1 standard, enterprises will actively participate in the formulation and revision of international standards, enhancing their right to speak in the global market.

7. Conclusion

EN 10216-1 P195 steel pipe, as a typical non-alloy seamless steel pipe for pressure purposes, has won a stable market position due to its excellent weldability, good ductility and high cost-effectiveness. This paper comprehensively explores the related issues of EN 10216-1 P195 steel pipe, and the main research conclusions are as follows: Firstly, the EN 10216-1 standard defines clear technical requirements for P195 steel pipe, including two quality grades of TR1 and TR2, which are suitable for different application scenarios with different safety requirements. The low carbon content and strictly controlled harmful element content in the chemical composition of P195 steel pipe lay the foundation for its excellent comprehensive performance. Secondly, the manufacturing process of P195 seamless steel pipe involves multiple links such as steelmaking, billet heating, piercing, rolling, heat treatment and finishing. The key control of process parameters (such as smelting temperature, rolling speed, heat treatment system) is the core to ensure product quality. Thirdly, the full-process quality control system and scientific testing methods (such as chemical composition testing, mechanical property testing, non-destructive testing) provide an important guarantee for the stable performance of P195 steel pipe. Fourthly, P195 steel pipe is widely used in thermal power generation, petrochemical industry, urban heating and water supply and other fields. Practical cases have verified its good application effect and economic benefits. Fifthly, the current market demand for P195 steel pipe is stable, but it also faces challenges such as alternative materials, environmental protection policies and fierce market competition. Its future development will focus on intelligent upgrading, green transformation, product performance enhancement and application expansion.

Although P195 steel pipe has achieved remarkable development in production technology and industrial application, there are still some areas that need further improvement. For example, in the field of high-corrosion and high-temperature applications, its performance still has a certain gap compared with alloy steel pipes; the intelligent level of some small and medium-sized production enterprises is relatively low, which affects the stability of product quality. In the future, relevant research can focus on the development of high-performance modified P195 steel pipe, the optimization of intelligent production technology, and the exploration of new application scenarios. With the continuous advancement of technological innovation and green development, EN 10216-1 P195 steel pipe will continue to play an important role in the medium and low pressure application fields, and its application prospects will be broader.

You must be logged in to post a comment.