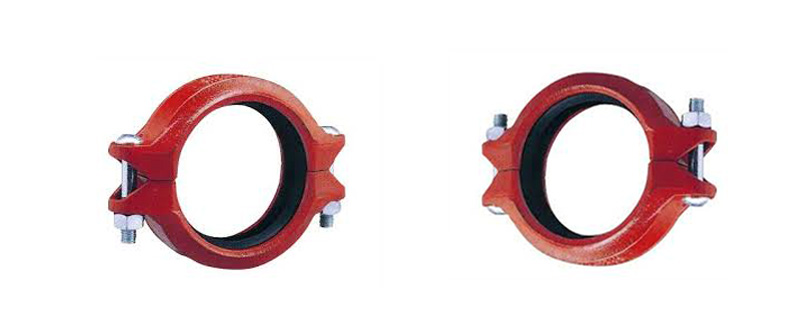

grooved pipe coupling clamp are often used on pipe connections on dry bulk tankers in place of welding offering the ability to adjust, change or replace pipe sections without the need for a permanent joint such as a weld.Widely used in municipal pipelines, power plants, mining industries, chemistry industry etc, which bear different media and high pressure industrial pipe lines.

Description of forged aluminum grooved pipe coupling clamp,grooved clamps

|

Inch |

Range |

Product size |

Screw |

Nut |

QTY |

Size/CTN |

G.W |

N.W |

|

1/4” |

11-15 |

1.5*20 |

M6 |

M8 |

300 |

42*27*13 |

15.5 |

51 |

|

3/8″ |

16-20 |

1.5*20 |

M6 |

M8 |

300 |

42*27*13 |

16.8 |

56 |

|

1/2″ |

20-24 |

1.5*20 |

M6 |

M8 |

250 |

42*27*13 |

15 |

59.2 |

|

3/4″ |

25-30 |

1.5*20 |

M6 |

M8 |

200 |

42*27*13 |

13.4 |

66 |

|

1″ |

32-38 |

1.5*20 |

M6 |

M8 |

150 |

42*27*13 |

11.2 |

74 |

|

1-1/4″ |

39-46 |

1.5*20 |

M6 |

M8 |

125 |

42*27*13 |

10 |

79 |

|

1-1/2″ |

48-53 |

1.5*20 |

M6 |

M8 |

200 |

42*27*25 |

17.4 |

85 |

|

54-58 mm |

54-58 |

1.5*20 |

M6 |

M8 |

150 |

42*27*25 |

14.6 |

95 |

|

2″ |

59-66 |

1.5*20 |

M6 |

M8 |

150 |

42*27*25 |

15.8 |

103 |

|

2-1/2″ |

74-80 |

2.0*25 |

M6 |

M10 |

100 |

42*27*25 |

19.2 |

188 |

|

3″ (nut M10) |

87-94 |

2.0*25 |

M6 |

M10 |

80 |

42*27*25 |

17.2 |

210 |

|

99-108 mm |

99-108 |

2.0*25 |

M6 |

M10 |

70 |

42*27*25 |

16.4 |

229 |

|

4″ |

110-116 |

2.5*25 |

M6 |

M10 |

50 |

42*27*25 |

14.8 |

288 |

|

120-129 mm |

120-129 |

2.5*25 |

M6 |

M10 |

50 |

42*27*25 |

15.9 |

310 |

|

129-135 |

129-135 |

2.5*25 |

M6 |

M10 |

45 |

42*27*25 |

14 |

303 |

|

5″ |

135-143 |

2.5*25 |

M6 |

M10 |

30 |

42*27*25 |

10 |

320 |

|

149-161 mm |

149-161 |

2.5*25 |

M6 |

M10 |

30 |

42*27*25 |

11.9 |

384 |

|

6″ |

162-170 |

2.5*25 |

M6 |

M10 |

25 |

42*27*25 |

10.1 |

388 |

|

8” |

207-219 |

2.5*25 |

M6 |

M10 |

25 |

42*27*25 |

12.8 |

496 |

Features of forged aluminum grooved pipe

Precision forged to provide an exact fit and great appearance

Precision casting and machined dimensions provide an exact fit and great appearance

Unlike steel groove clamps that secure pipe ends with high clamping force against tubing/piping walls, the Dixon aluminum clamp takes the full bolt force and locks into the groove of the tube/pipe, preventing distortion of the tube/pipe diameter.

Easy to preform maintenance

Leak-tight connection

You must be logged in to post a comment.